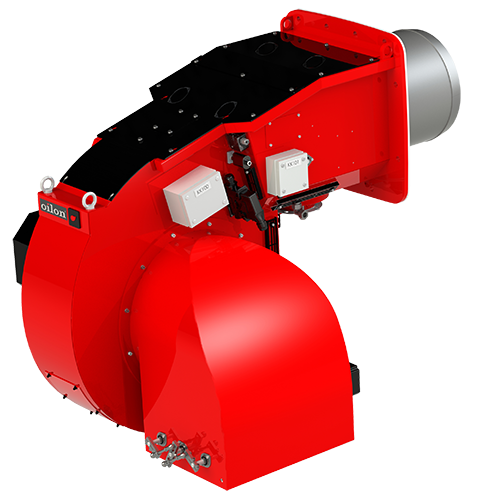

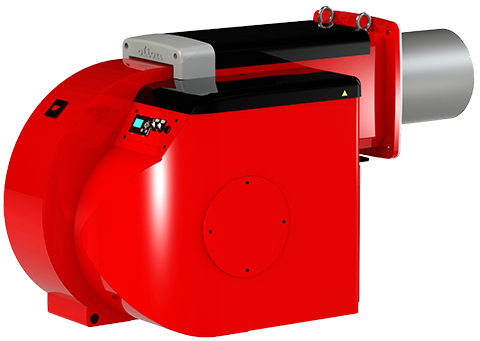

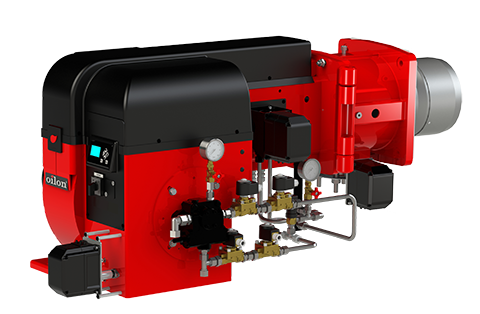

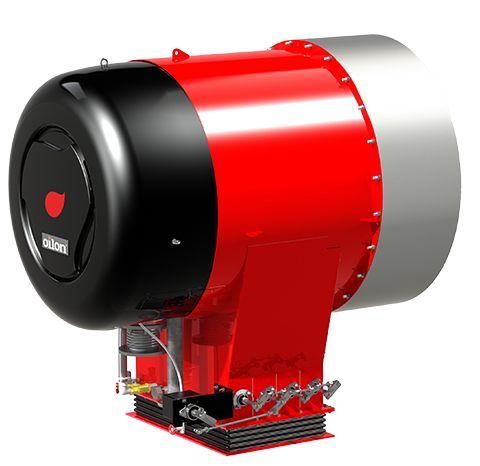

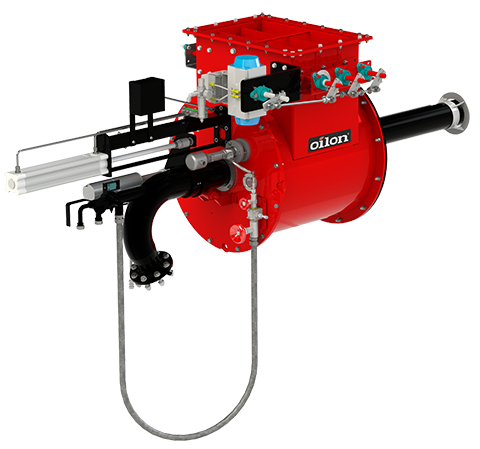

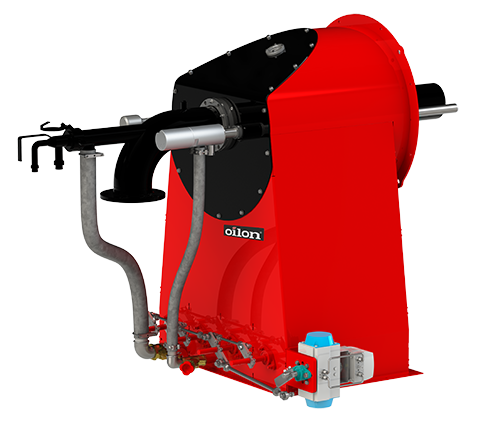

FILTER is an authorized representative of Oilon burners. The excellent performance and reliability as well as the low emissions of Oilon burners are the result of decades of experience and long development. Depending on the solution, our burners can achieve the most stringent emission requirements in the world.

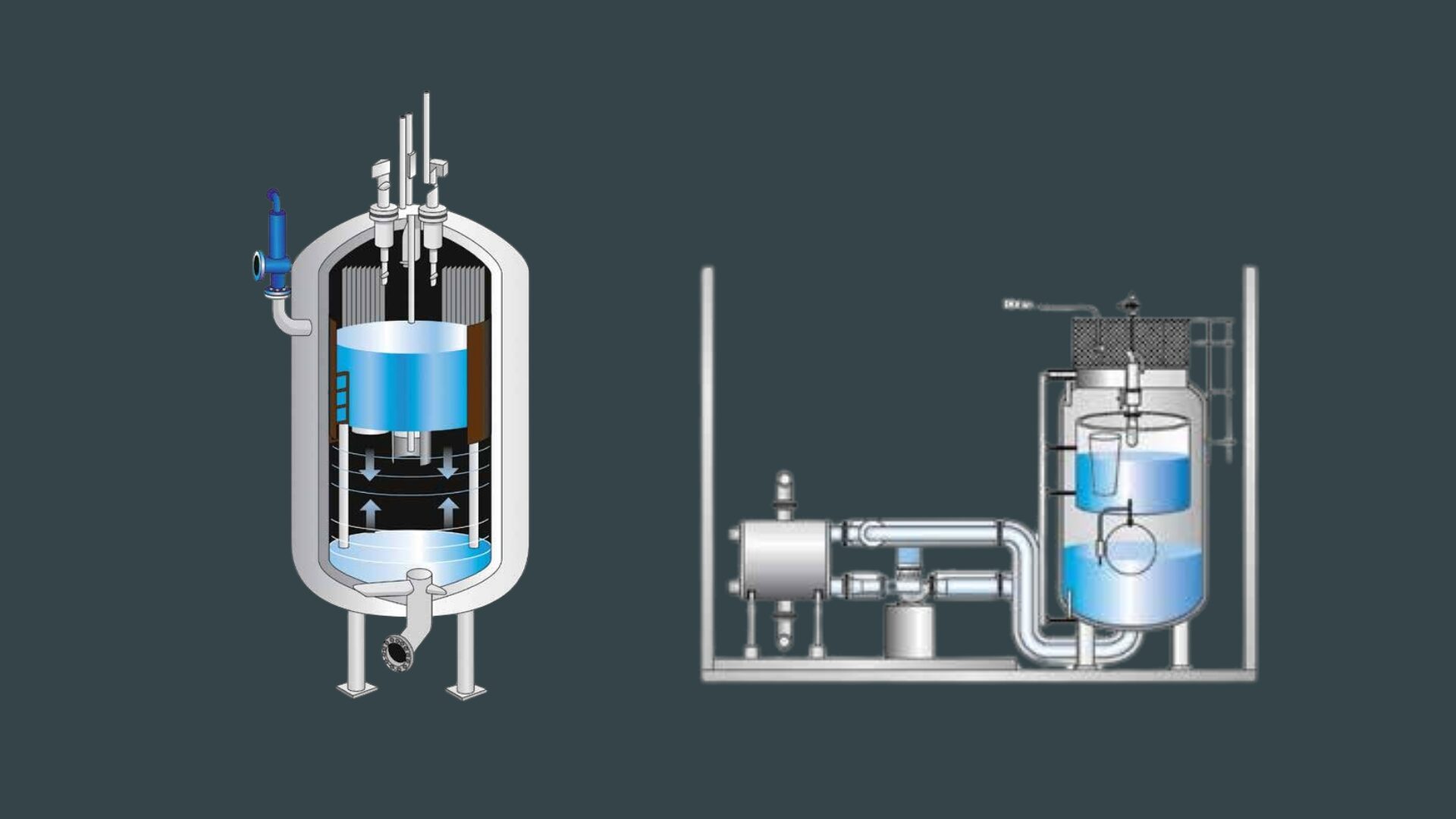

The burners are used in categories such as gas/oil-fired boilers, thermal oil heaters, fluidized bed boilers, recovery boilers, grate boilers, rotary kilns, hot air generators, and process furnaces.

The following parameters assist us in choosing the most appropriate burner for your specific application:

- Fuel type

- Boiler power and efficiency, or required burner efficiency

- Boiler back pressure

- Fuel pressure before the burner

- Burner control: step-fired or modulating

The product images are for illustrative purposes, and the actual product may appear different from the one shown in the pictures.

Please note: Product selection may vary in different countries where we operate.