This project is a great example of how energy independence, environmental responsibility, and efficiency can come together in a single solution! AS Tallinna Vesi’s goal is to reduce electricity consumption at its wastewater treatment plant and increase the facility’s energy self-sufficiency. Previously, the potential of the biogas generated from sewage sludge was not fully utilized. As a responsible company, Tallinna Vesi aims to reduce its environmental impact, meet the EU’s renewable energy targets, and improve overall energy efficiency.

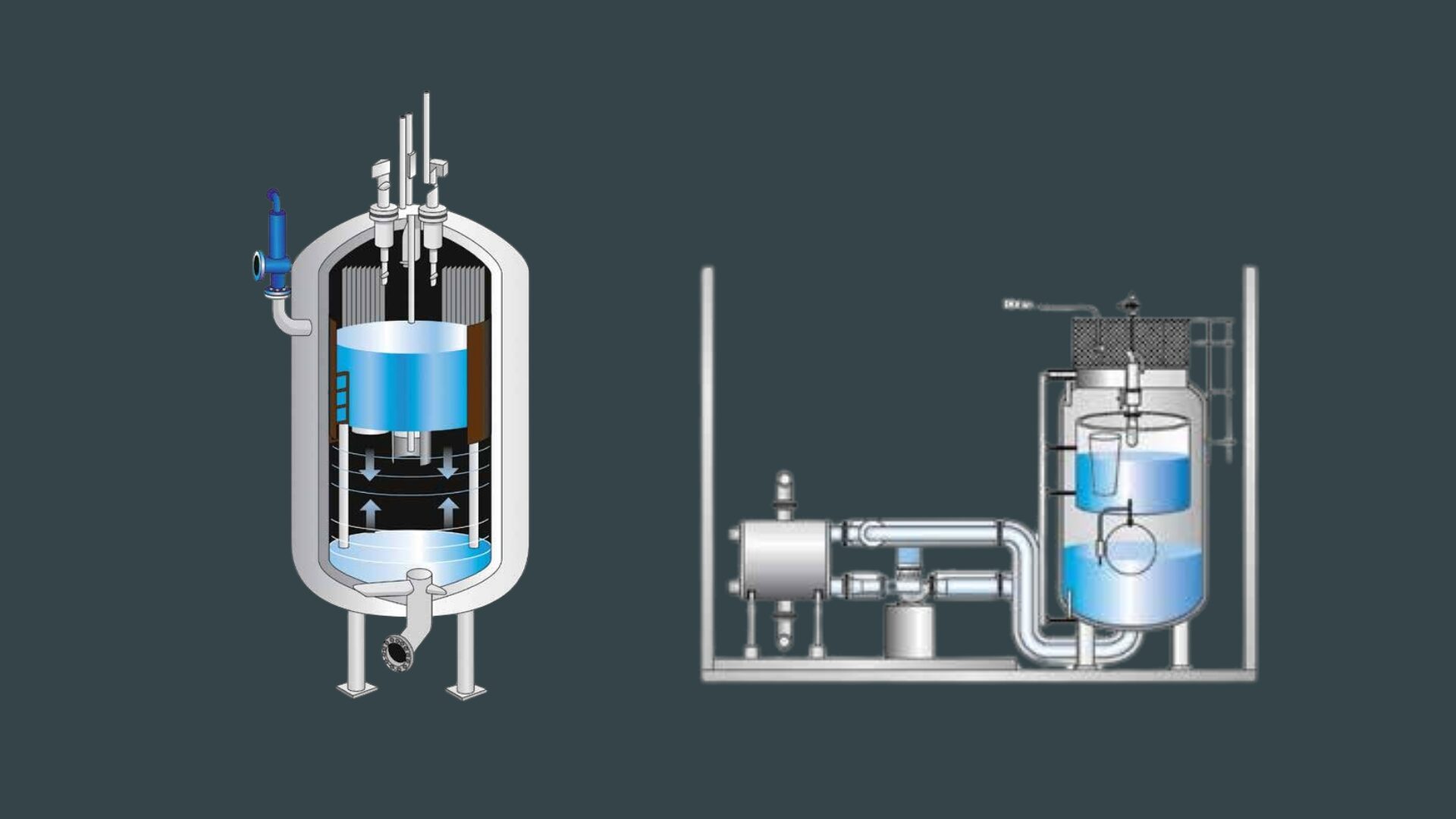

FILTER designed, built, and installed the new 5 MW combined heat and power (CHP) plant at the Paljassaare site, enabling much more efficient use of biogas. The plant features 2.1 MW of electricity generation and up to 2.2 MW of heat generation capacity. The system includes a biogas purification unit, two INNIO Jenbacher gas engines, and a heat exchange hub (oil heat exchanger, cooling water heat exchanger, flue gas heat exchanger, and intake air heat exchanger). A new biogas pipeline was constructed to supply the CHP plant, equipped with flow meters, drying, compression, and purification units. Purified biogas can also be directed to existing gas boilers in the boiler house, increasing both system flexibility and overall efficiency. FILTER’s team is responsible for preventive maintenance of the plant to ensure smooth and reliable operation.