FILTER carried out the full design of a new steam boiler house for a leading Lithuanian producer of rapeseed oil, protein-rich animal feed, and biodiesel. The generated steam is used in the client’s manufacturing processes. Scope of work involved project management, design & engineering, installation & commissioning, automation.

Technical solution: FILTER designed and delivered a boiler house equipped with two natural gas-fired steam boilers, each with a capacity of 8,500 kg/h of steam (thermal power 5,800 kW each). Total steam production: 17,000 kg/h

• Supply to consumers: 15,700 kg/h

• Boiler house own needs: 1,300 kg/h

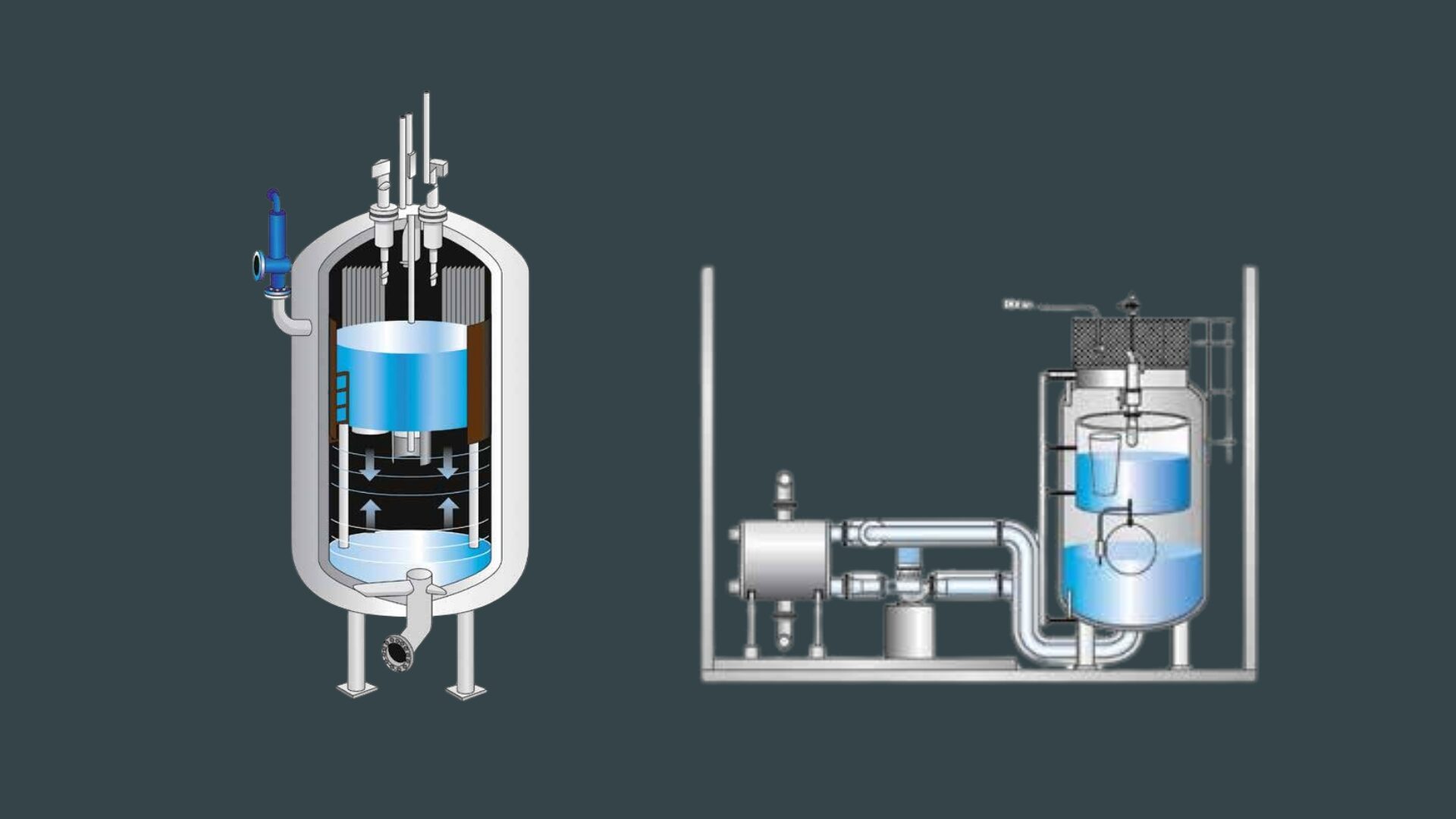

The water treatment system includes mechanical water filters, water softening filters, and a reverse osmosis unit. Softened water is stored in a 10 m³ tank, while demineralized water is stored in a 6 m³ tank.

A thermal deaerator operating at 0.2 barg was designed for feedwater treatment, featuring a 15 m³ storage tank and a 20 m³/h deaeration column. Before entering the deaerator, demineralized water is preheated in a heat exchanger utilizing heat from the boilers’ continuous blowdown.

Main Equipment: 2 × Viessmann steam boilers M95B336 equipped with 2 × OILON natural gas burners GP-700M-III WD200