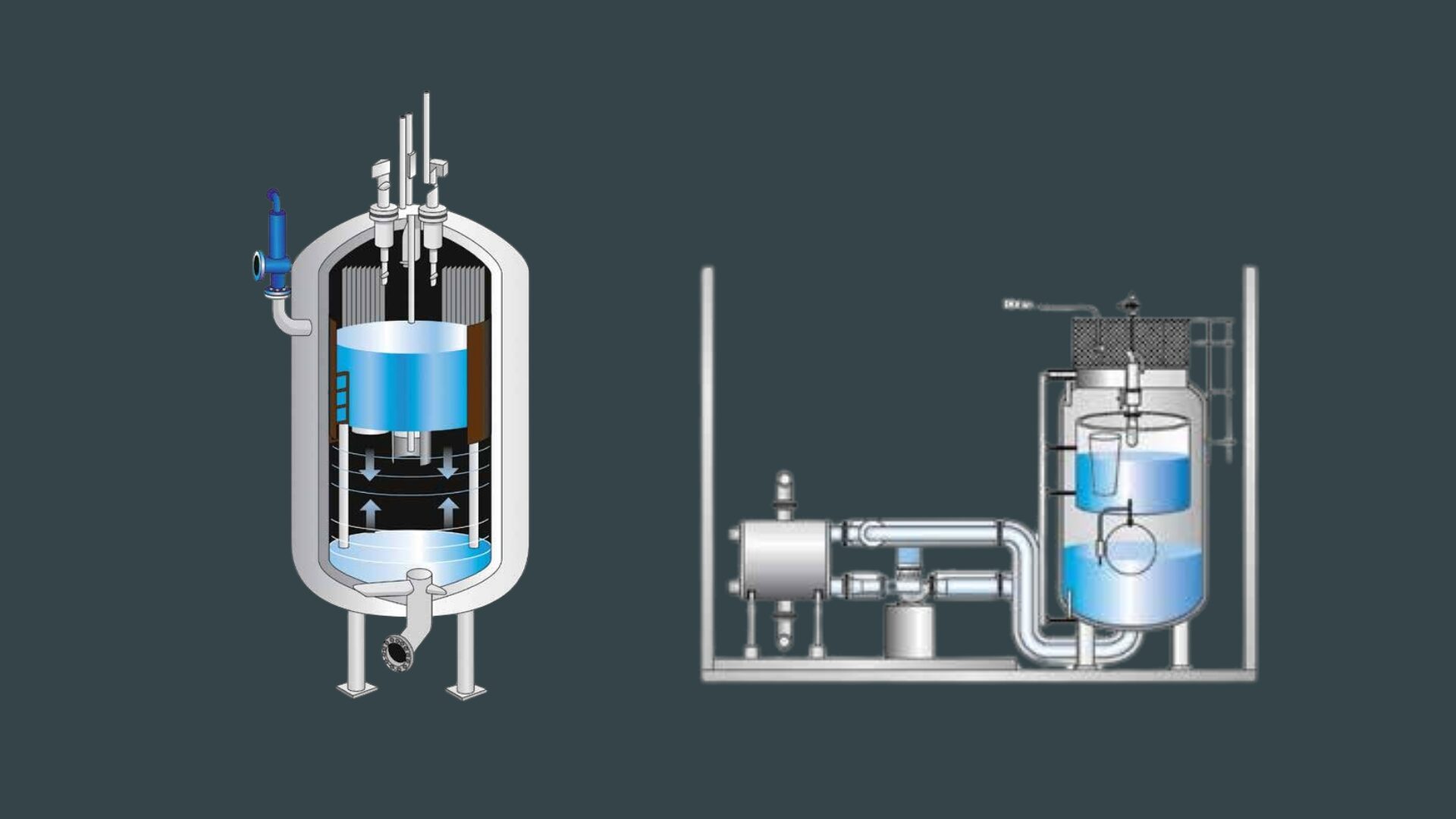

The project includes the delivery, installation, and design of two steam boilers, each with a capacity of 7000 kg/h and operating at a pressure of 10 bar. Each boiler is equipped with a Q=351 kW economizer and Oilon GP-600 burner that incorporate O2 control and an 18.5 kW frequency converter. The steam boiler’s water supply is ensured through a water service module with a feedwater tank, complete with a deaerator and a total volume of 8 m³. To ensure optimal water quality, the project features a 10 m³/h water treatment module equipped with an iron removal system, a water softener, a reverse osmosis (RO) system, and a 5 m³ storage tank with two frequency-controlled feedwater pumps.

All of this is integrated into a smart automation control system for seamless management and efficiency throughout the system.

A new steam boiler house will provide essential steam for production while also delivering heating and hot water for both operational and administrative needs. A key feature is its ability to regenerate residual heat from refrigeration equipment and compressor cooling, transforming it into reusable thermal energy.