Besides traditional HFC refrigerants, we offer HFO refrigerants with an extremely low or near-zero global warming potential (GWP). Our heat pumps are a flexible solution that can be used for different heating and cooling applications in industrial operations and large properties as well as for district heating and cooling.

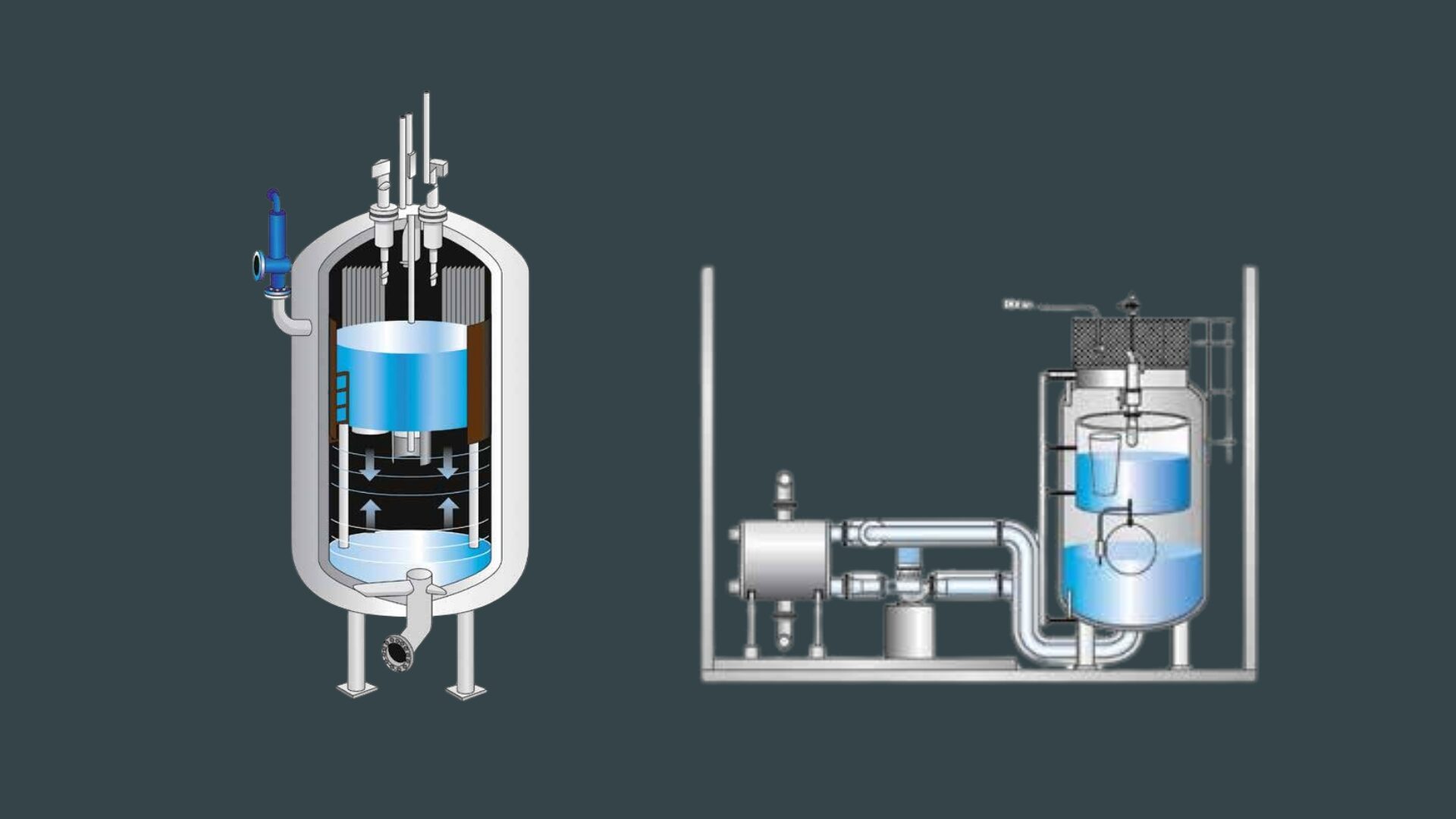

The best coefficient of performance can be achieved with combined heating and cooling (CHC). In CHC solutions, a heat pump cools down one part of a process and uses the extracted energy to heat up another part of the process, thus reducing the need for traditional forms of heating. This arrangement can be used to create a fully carbon-neutral heating and cooling solution.

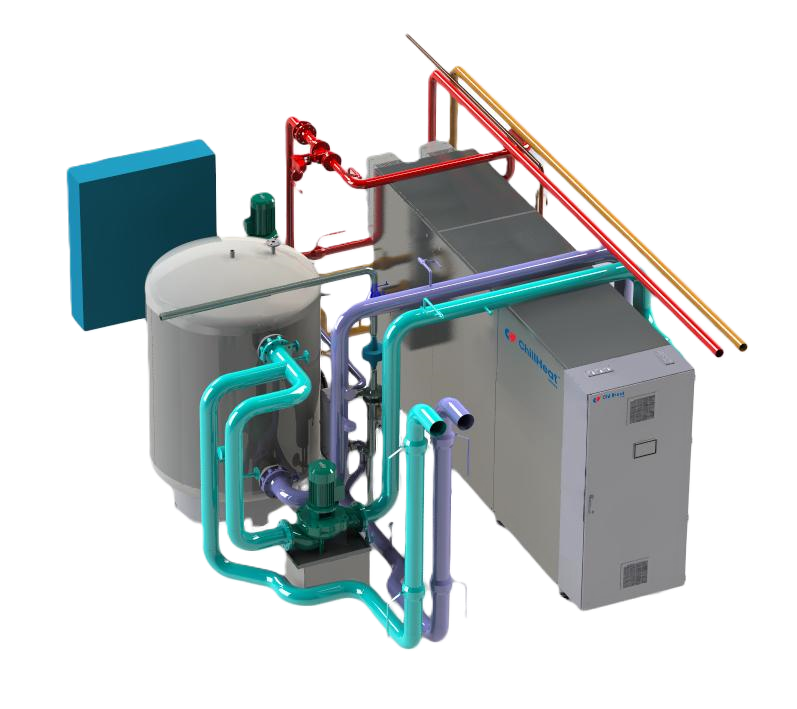

Oilon ChillHeat units can be combined into different systems. By connecting heat pumps together, the system’s capacity can be increased, the system’s flow temperature increased, or both.

Applications:

- District heating and cooling

- Process heating and cooling for industry

- Large buildings

The product images are for illustrative purposes, and the actual product may appear different from the one shown in the pictures.

Please note: Product selection may vary in different countries where we operate.