The customer was operating a boiler house automation system installed in 2007, based on a Siemens S7-200 controller. As the system had become outdated — with limited support and no longer available spare parts — reliability issues emerged. The biggest concern was that alarm messages were no longer being sent via SMS, and system stability was decreasing.

Our solution

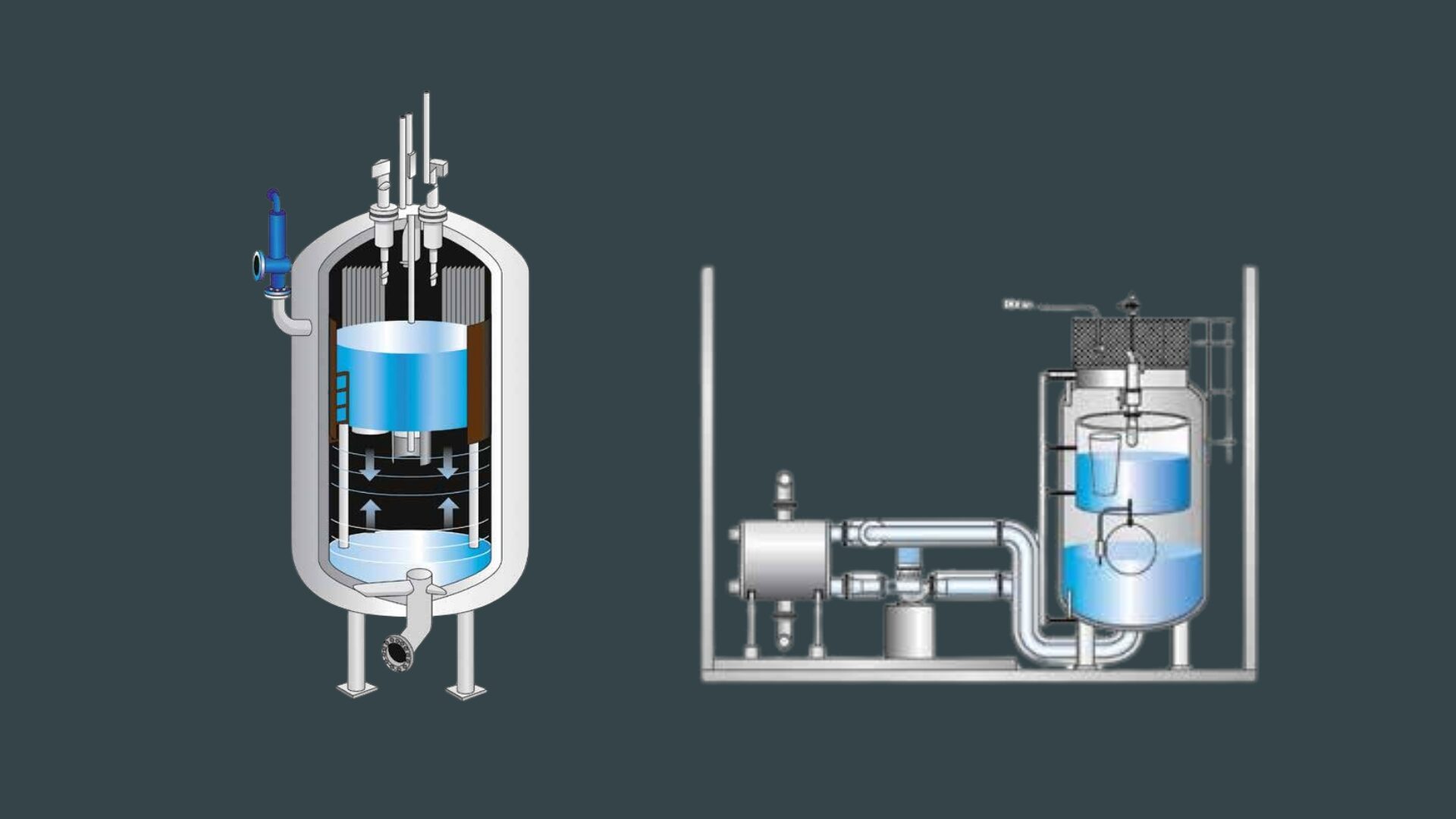

FILTER delivered a modern and more powerful Siemens S7-1500 series boiler house automation solution. We supplied a new automation panel with the program. With the new system, the customer gained a better overview of the boiler house’s operating status and the ability to conveniently change settings on site by the operator – intervention by automation is no longer necessary, for example, to change the central heating temperature.

In addition, we have implemented a new alarm notification solution that sends notifications via e-mail. The maintenance team also has the option of remotely controlling the boiler room and performing diagnostics.

- Modern automation controller and solution

- New automation panel and specially adapted program

- Alarm notification via e-mail

- Remote control and diagnostics option

- Independent operation by on-site operator

The three most important benefits of implementing Siemens S7-1500:

- Increased reliability and speed

S7-1500 controllers are significantly faster and more reliable than their predecessors (e.g. S7-200). This means more precise process control and a lower risk of malfunctions. - Improved cybersecurity

The controller has built-in encrypted data communication, authentication, and user levels. This ensures a higher level of cyber security – especially important for remote control. - Expandable and future-ready

The platform supports module-based expansion, allowing for easy future upgrades to the system. Well suited for Industry 4.0 solutions (e.g. IoT, cloud analytics).