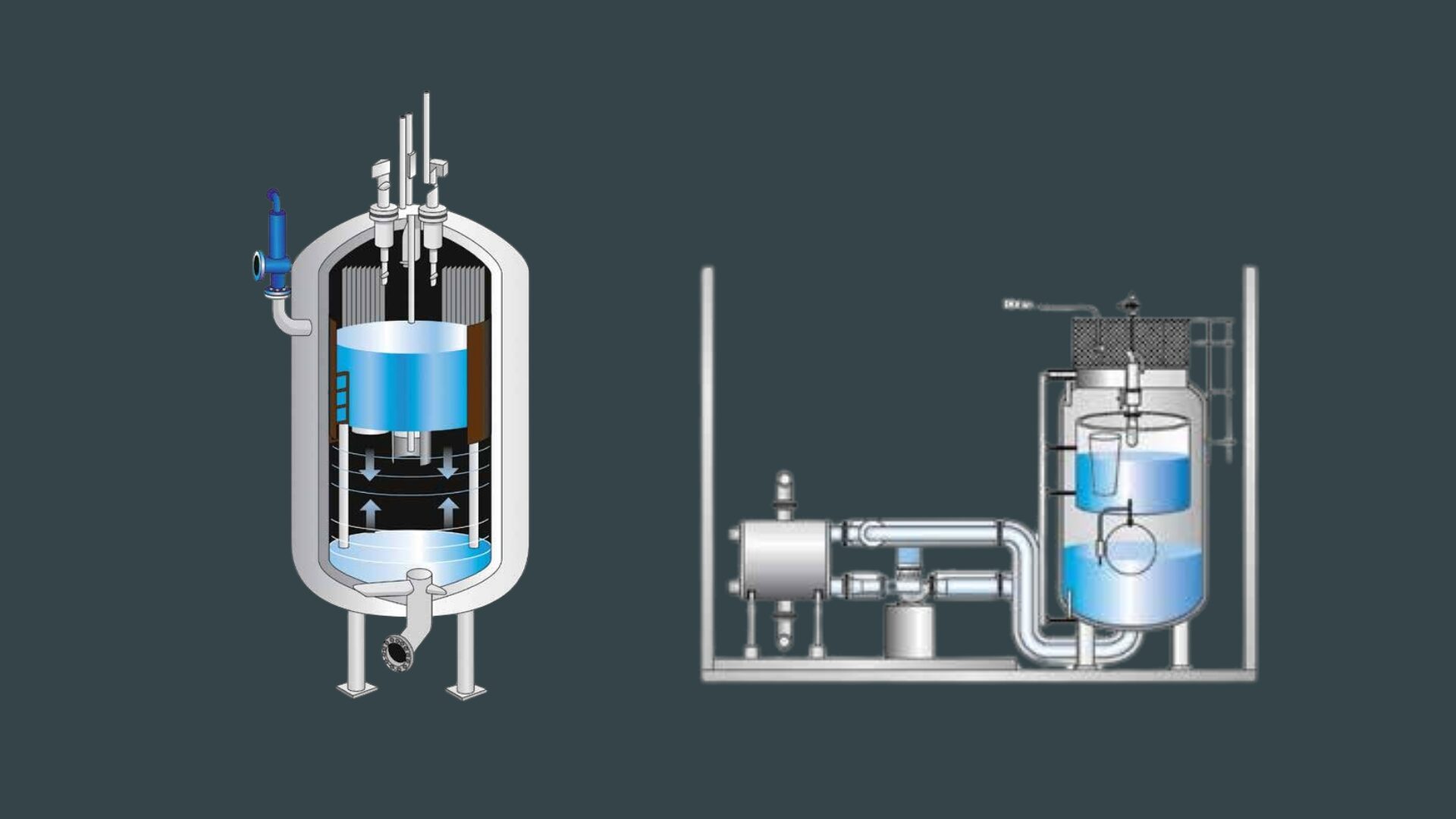

This FILTER project involved the delivery and installation of a hydrochloric acid (HCl) tank at a brewery. The scope of work included all necessary preparatory demolition work for replacing the existing tank, site preparation, and the installation and commissioning of the new tank. The project featured a double-walled DN2800 hydrochloric acid tank with level control and all materials required for installation. The working volume of the tank is 30m³, with a full volume of 31m³. The tank operates under a hydrostatic working pressure in an environment containing 35% HCl. It is located above ground and complies with EN 13121-3 standards. The installation of this tank will help ensure consistent pH control and effective cleaning processes, which are critical for maintaining the high quality of the beer produced. It also supports the brewery’s operations by providing a reliable and safe storage solution for hydrochloric acid, contributing to the overall efficiency and safety of production processes.