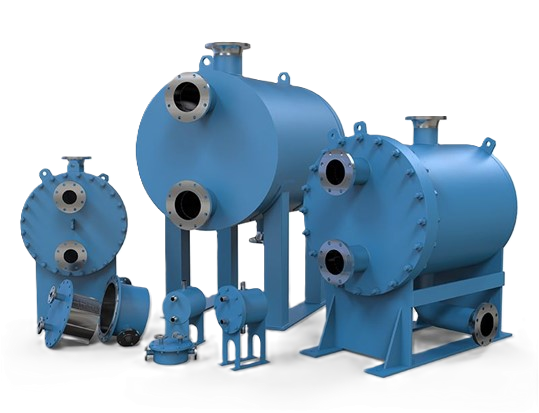

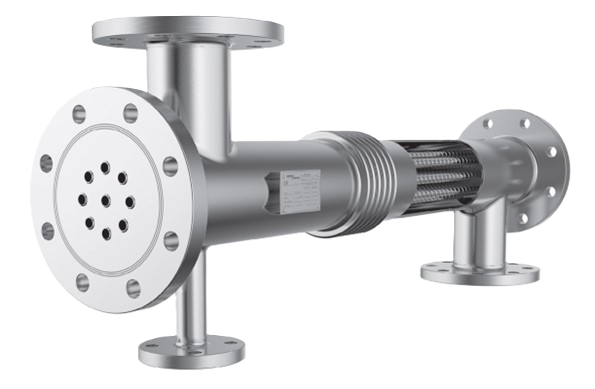

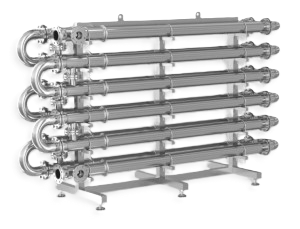

We collaborate with leading original equipment manufacturers worldwide to deliver high-quality heat exchangers and spare parts. Heat exchangers find applications in industries where efficient thermal management is crucial for processes, product quality, safety, and energy efficiency. Their versatility makes them indispensable for optimizing temperature conditions in diverse industrial settings.

-

Reliability and high quality

-

Customized solutions

-

Energy efficiency

-

Cost-effective solutions

-

Comprehensive support