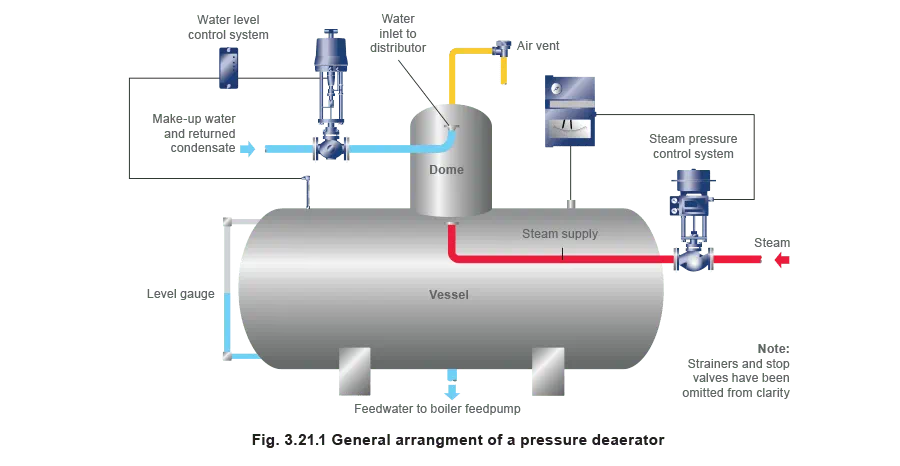

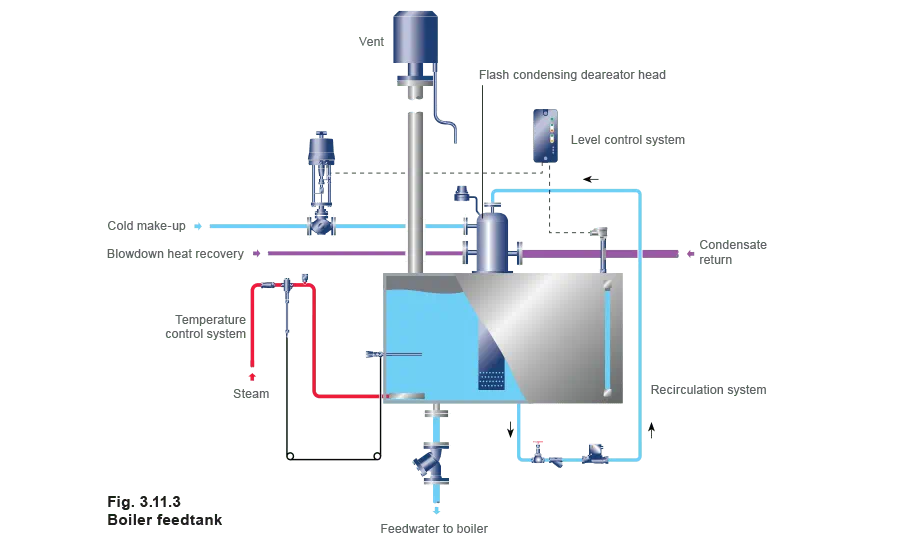

Deaerators are used in steam systems to eliminate oxygen from boiler feed water while storing and mixing returning condensate with fresh make-up water. Our deaerator units are fully equipped with automatic controls, instruments, and safety features. We can provide a tailor-made design to fit your capacity and room dimensions.

-

Safe steam production

-

Extended lifespan of the steam boiler plant

-

Efficient steam production

-

Customized design

-

Compact prefabricated unit