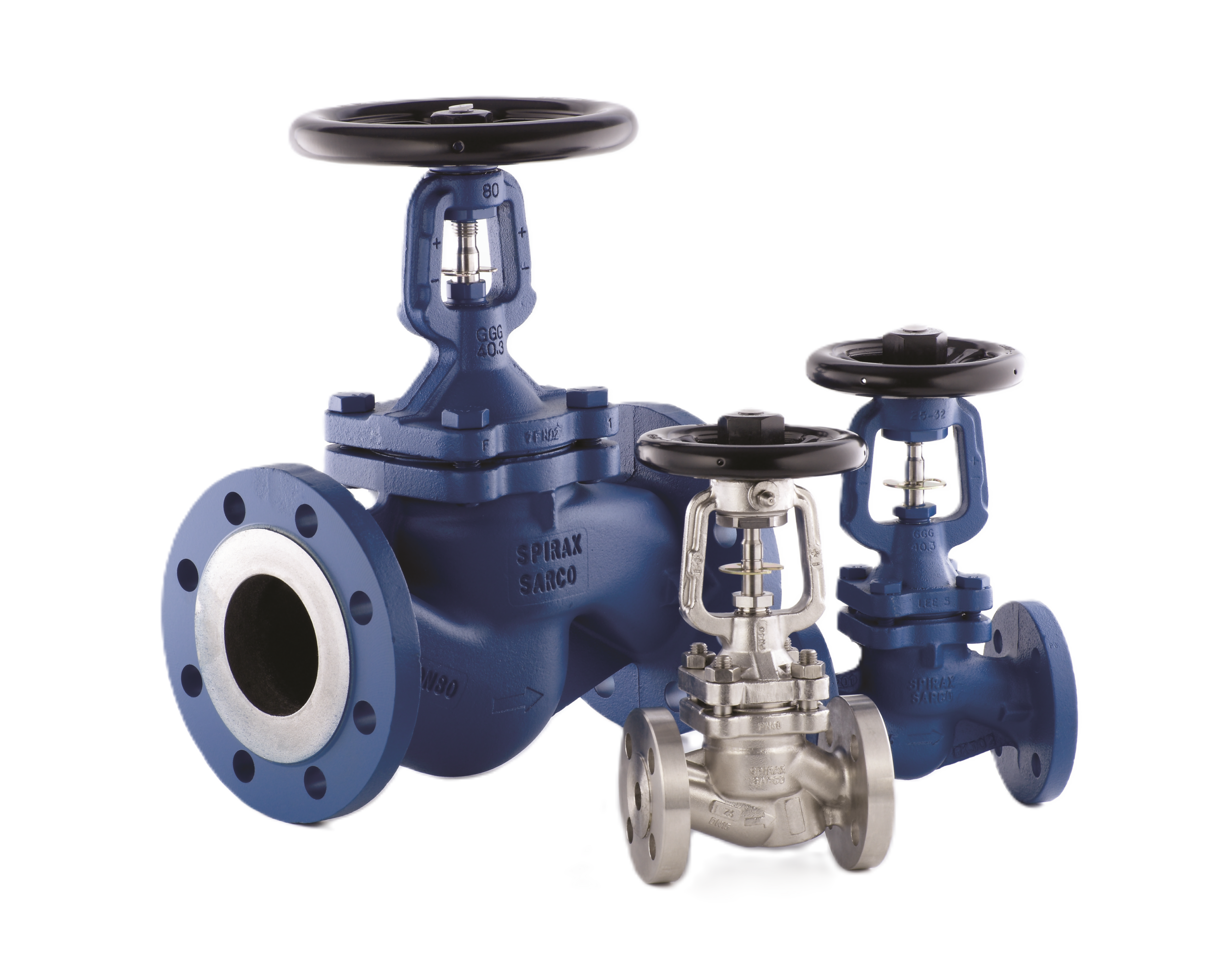

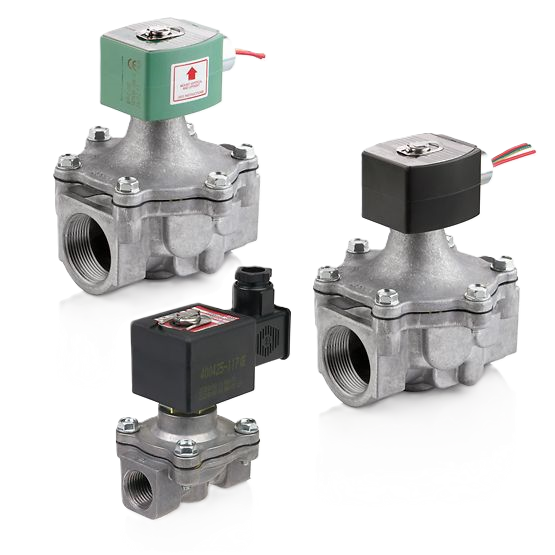

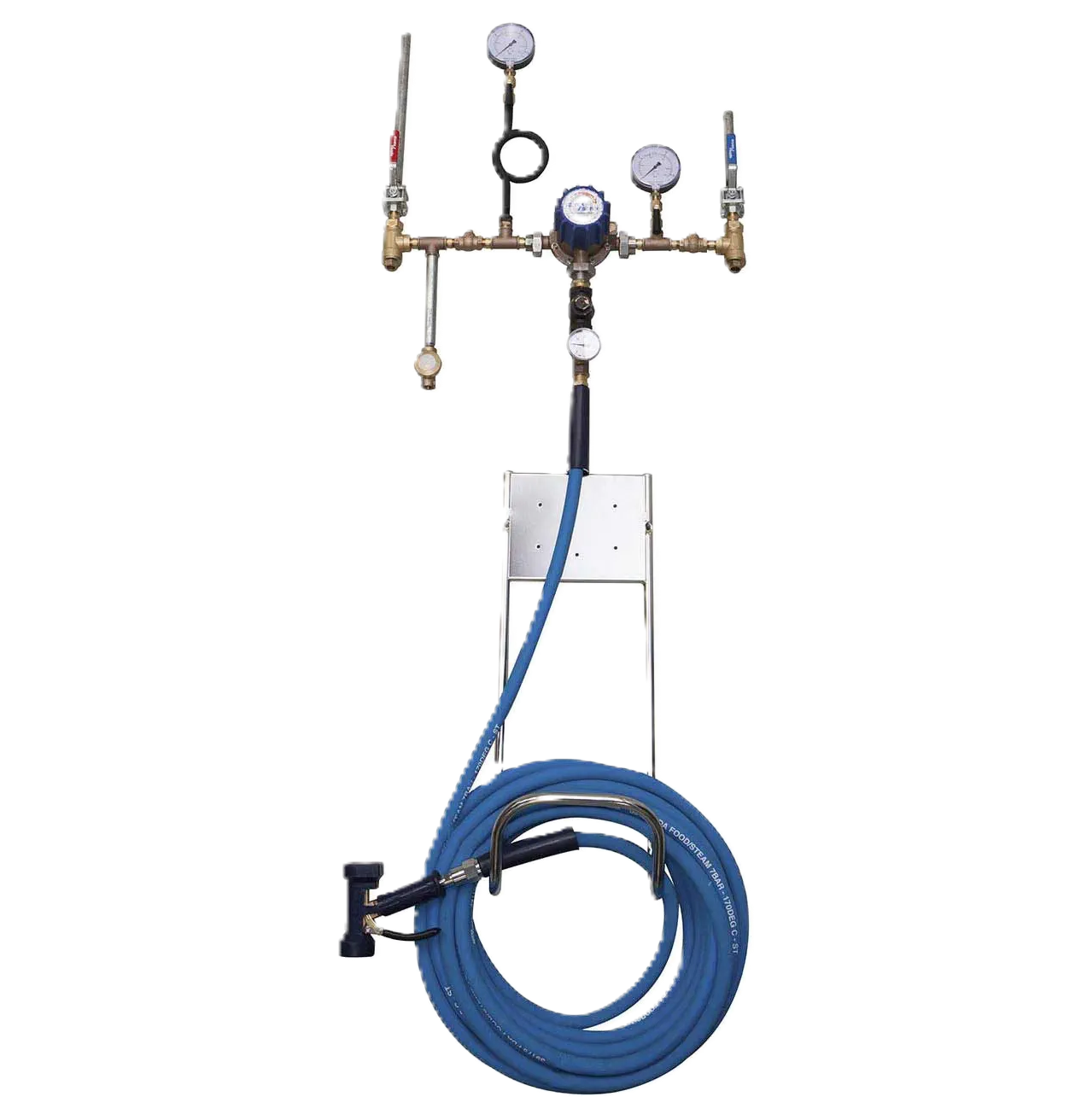

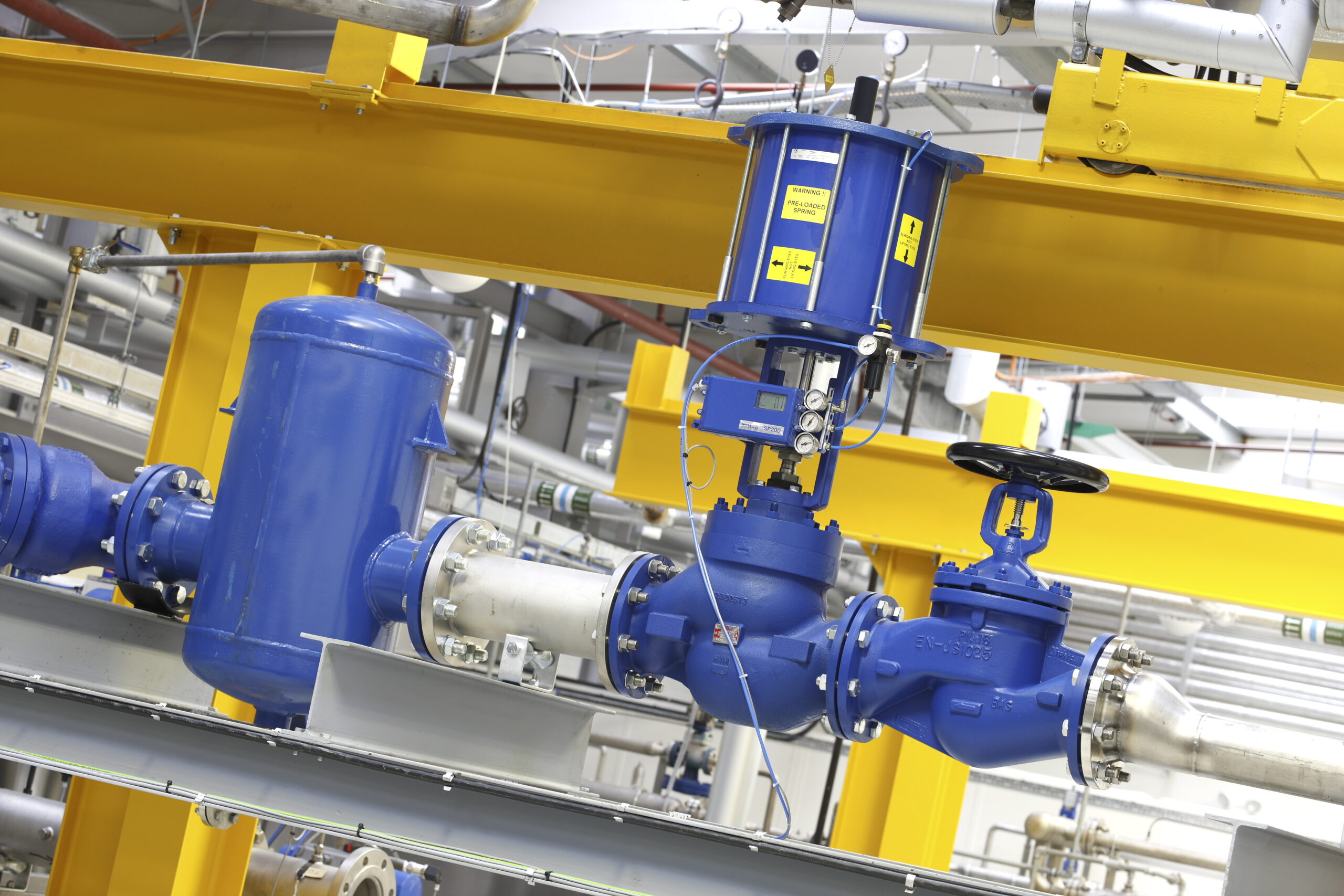

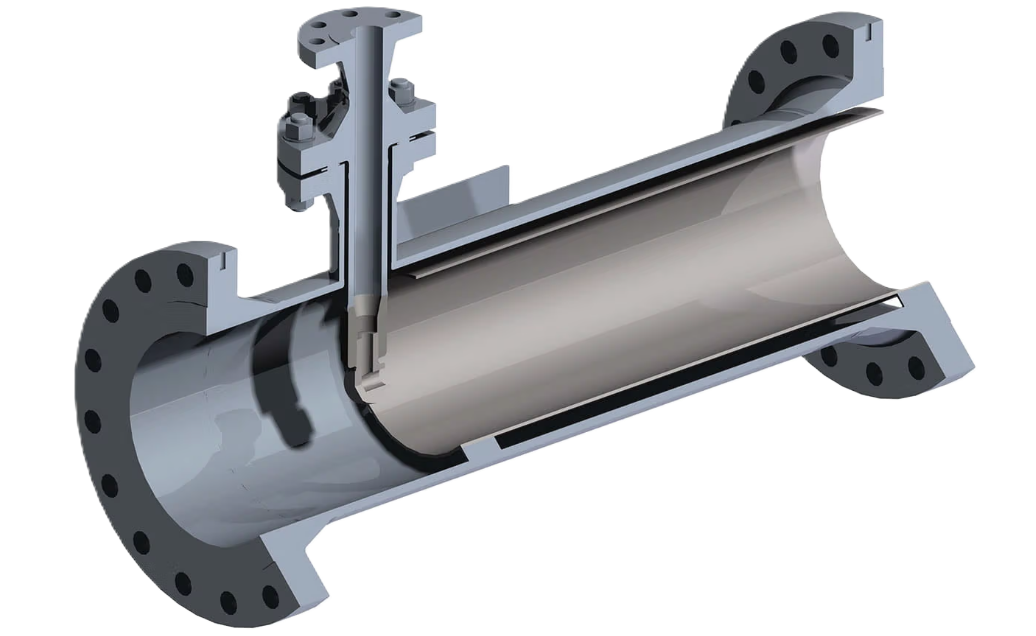

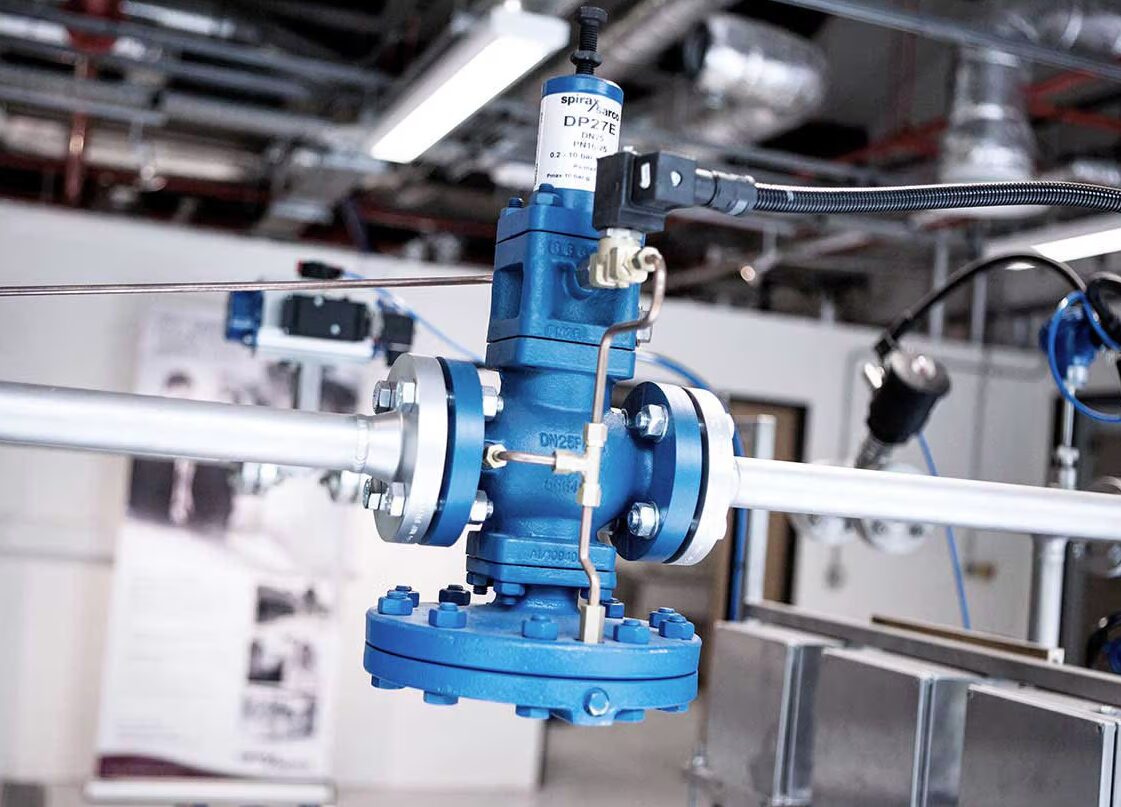

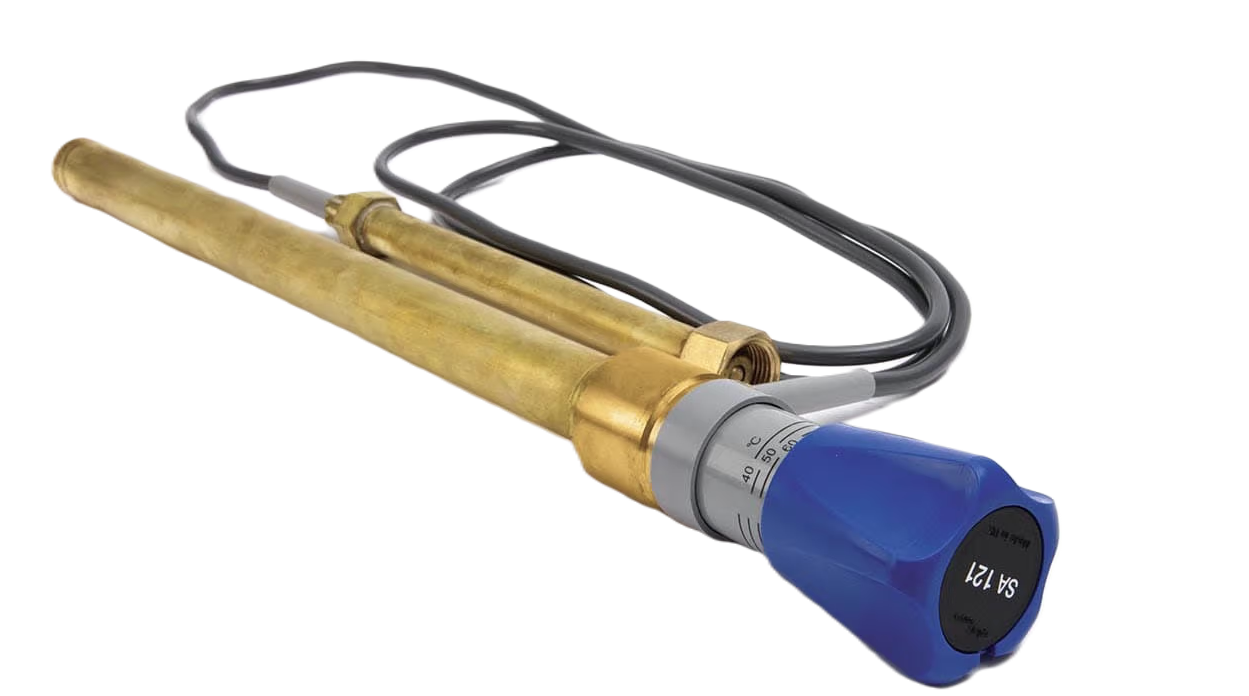

A comprehensive range of the highest-quality valves and pipe ancillaries is available for the control and efficient use of steam, industrial gases, water, and other liquids. These products can be provided to compose systems. If you want to guarantee that your system operates effectively, order your system engineering and supply from our experts!

-

Diverse product range

A wide array of products for efficient use of steam, industrial gases, water, and other liquids

-

Convenience

Get all the valves and pipe ancillaries from one place

-

Quality

High-quality products from trusted partners