Electric steam boilers can be used in various applications: direct power-to-heat; as a backup energy source independent of the primary fuel; to cover peak loads; electrical grid regulation; emission reduction and avoidance of CO2 trading.

Electric steam boilers can be used in various applications: direct power-to-heat; as a backup energy source independent of the primary fuel; to cover peak loads; electrical grid regulation; emission reduction and avoidance of CO2 trading.

As electricity is more and more used as the primary energy source both in housing and in transport sector, then in industrial sector we can also see it finally trending. If steam usage is intermittent and needed only a specific time of the day, the most easiest, conveniet and safest solution is an electric steam boiler. The boilers are available with outputs from 10 kW up to 75 MW and for both low and high steam pressure boilers (up to 85 barg). Electrical steam boilers can be used in low voltage or high voltage ranges.

Our solutions provide peace of mind for any industry

Bigger high-voltage electrode boilers can be used for energy and power production plants (including co-generation) to help with grid regulation, smart energy transaction between high and low electricity market prices and to avoid CO2 emission trading. Small and medium sized steam boiler can be used in all industries that use steam either providing a safe and reliable source of energy or by offering support on covering peak loads. If there is no other fuel source availability (gas, oil), electricity is the easiest choice.

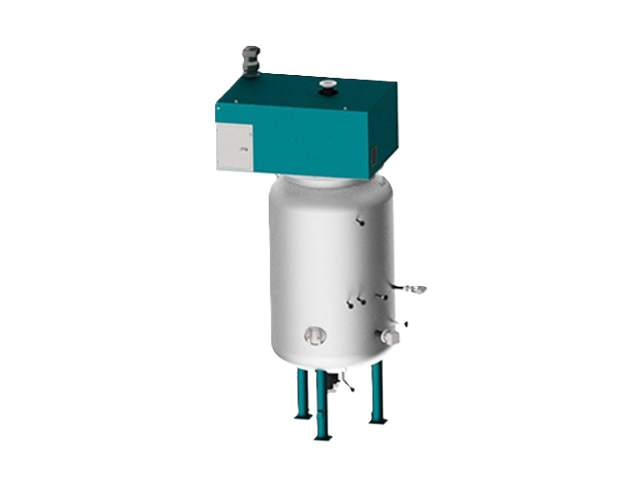

The product images are for illustrative purposes, and the actual product may appear different from the one shown in the pictures.

Please note: Product selection may vary in different countries where we operate.

Low voltage electric steam generators use electricity as fuel from the low voltage side of electrical grid (below 1000V). In low voltage steam boilers and steam generators the steam is generated by an electric resistor heating coil inside the boiler shell. Boiler range is modulated by the amount of heating elements in work. The boilers are available with outputs from 10 kW up to 20 MW and more. Low voltage steam boilers are mostly close to the end user of steam and can be used:

High Voltage Boilers are always electrode boilers. The working principles is based on natural water electrical resistance and conductivity: electrical current flows through the boiler water between the electrodes and neutral point. As the load is resistive the heat is generated in form of hot water or a steam.

High voltage electrode steam boilers use electricity as fuel from central voltage side of electrical grid (up to 25 kV).

The size of the boiler is very small – one unit can supply up to 75 MW. High voltage electrode boilers can be used:

Our steam production systems are designed so that customer's OPEX costs (costs for resources like electricity, water, chemicals, salts, service labor costs etc.) are as low as possible.With electrical steam boiler the efficiency of steam production is near 100%.

Electric operation does not require fuel (gas/oil) supply and chimney system. It uses green electricity instead of fuel. It means no emission, making an electrical steam boiler environmentally friendly.

Ensuring safety and security to all our solutions is our main foundation and key-point when implementing a design and selecting a product. All of our steam boilers are certified to local regulations and are equipped with all needed safety equipment for safe and smooth operation.

All electrical steam boilers are equipped with integrated control panel with accessable operator panel. As there is no combustion inside the boiler, the operation and service is very simple and easy to cover.