FILTER is INNIO Jenbacher gas engines authorized distributor and service partner.

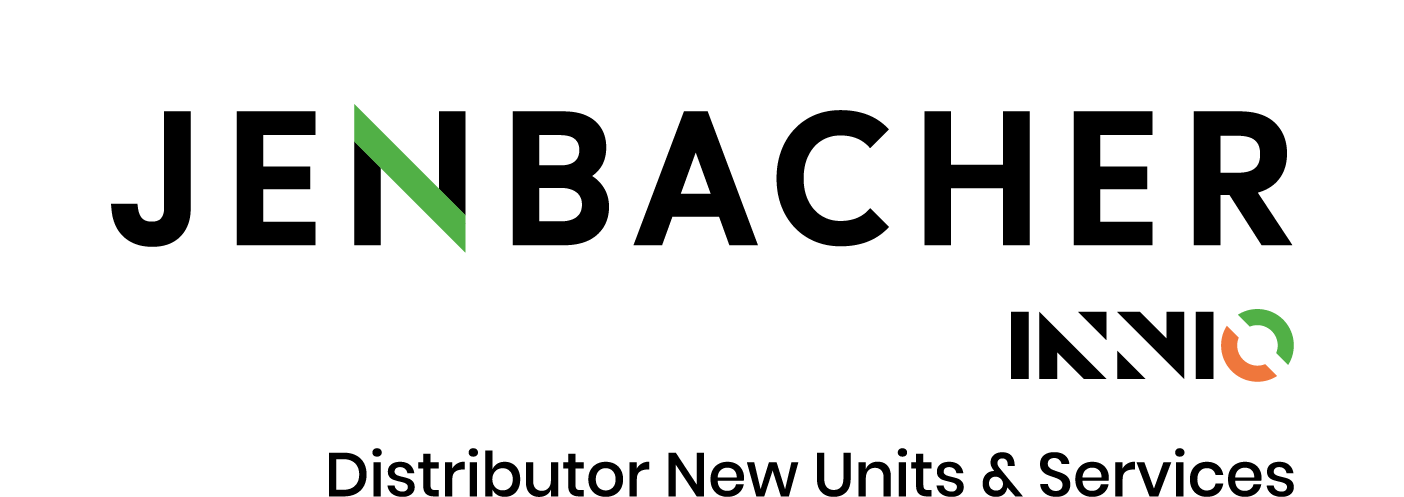

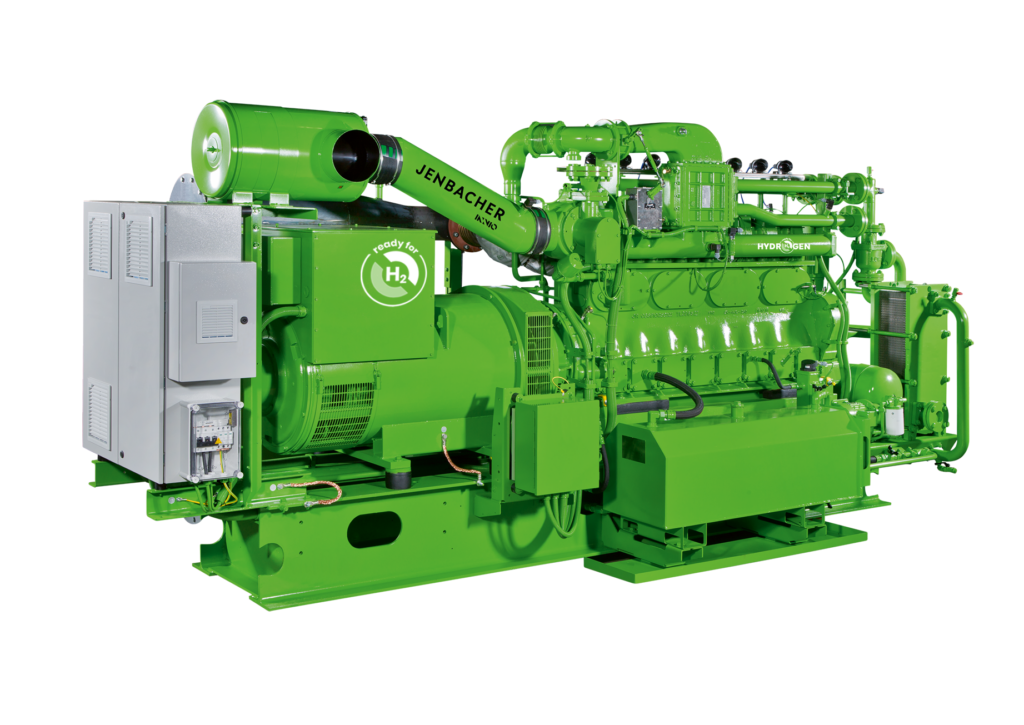

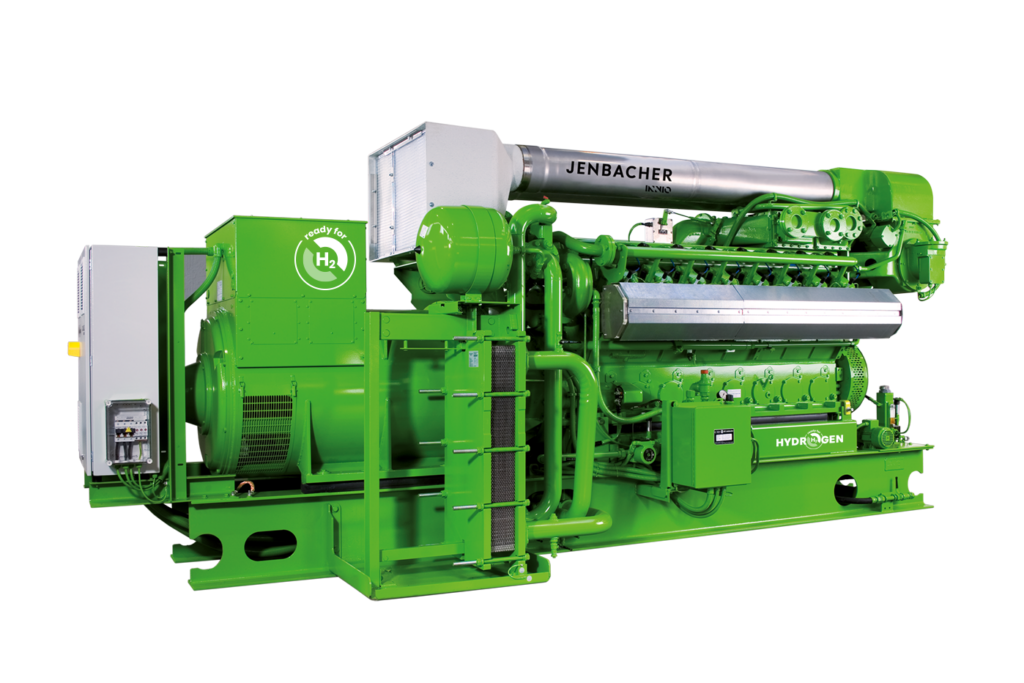

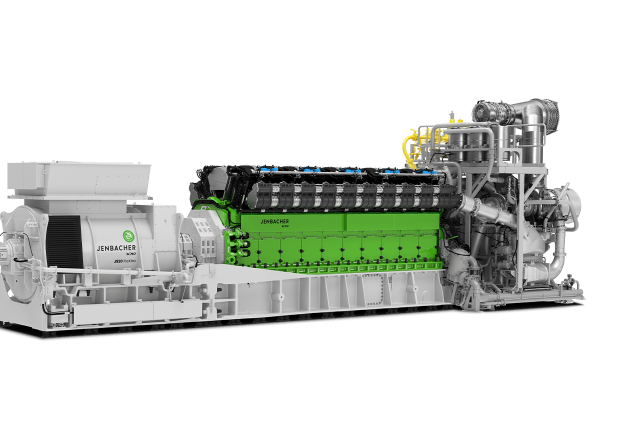

Jenbacher gas engines range in power from 0,25 MW to 10,4 MW, and the engines run on either natural gas or a variety of other gases. All Jenbacher gas engines are available as:

- GenSet: packaged generator sets for power generation only.

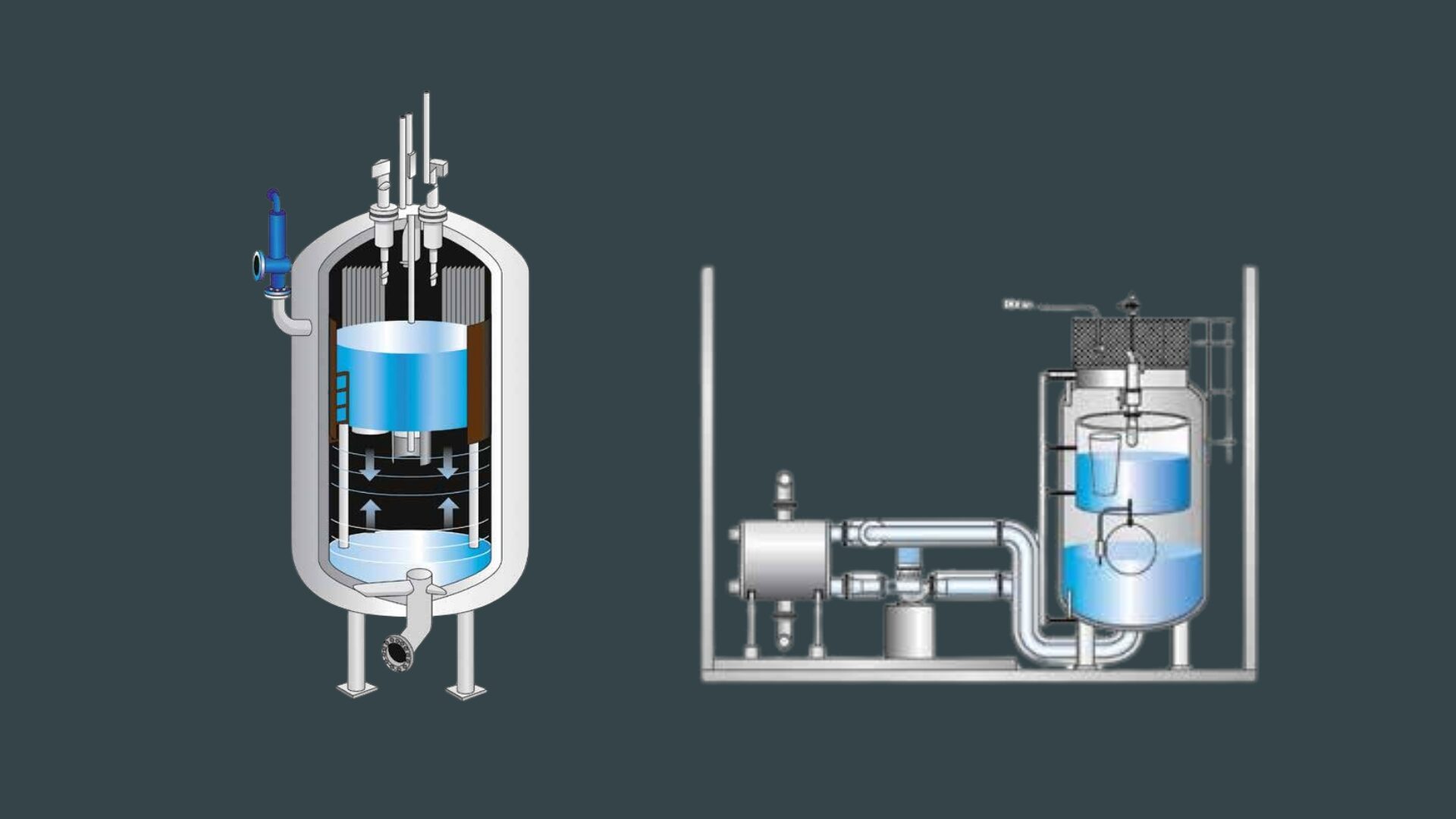

- CHP Module: simultaneous power and heat generation at a very high total efficiencies, reaching 90% and even more.

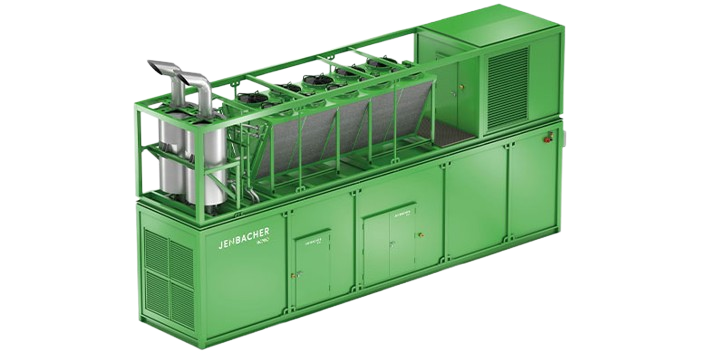

- Containerized solutions: “ready-to-use” power plants, available for GenSet and CHP module.

INNIO Jenbacher gas engine, together with generator, control system is oftenly used as a back-up or peak shaving generator. When supplemented with auxiliary equipment it forms Combined Heat and Power plant (CHP) for simultaneous production of electricity and heat, as well as cold (CCHP) which can be installed on site or delivered as a ready containerized unit.

A broad range of commercial, industrial, and municipal customers use Jenbacher products for on-site generation of power, heat, and cooling. We’ll help to filter out the specific product or solution that your industrial company needs!

* Provided technical data is for information only. Data ranges are calculated considering various gas quality levels and ambient conditions (standard or hot/tropical conditions, etc.). Jenbacher can change the technical data unilaterally. Output and efficiency at generator terminals. Energy input is according to DIN ISO 3046 and DIN 6271, respectively, with a tolerance of + 5%. All data according to full load and subject to technical development and modification. Based on emission values of 250 and 500 mg/Nm3 NOx at 5% O2 at dry exhaust gas. Base for biogas and sewage gas versions: 65% CH4 / 35% CO2. Base for landfill gas version: 55% CH4 / 40% CO2 / Rest N2.

** The product images are for illustrative purposes, and the actual product may appear different from the one shown in the pictures.

*** Please note: Product selection may vary in different countries where we operate.