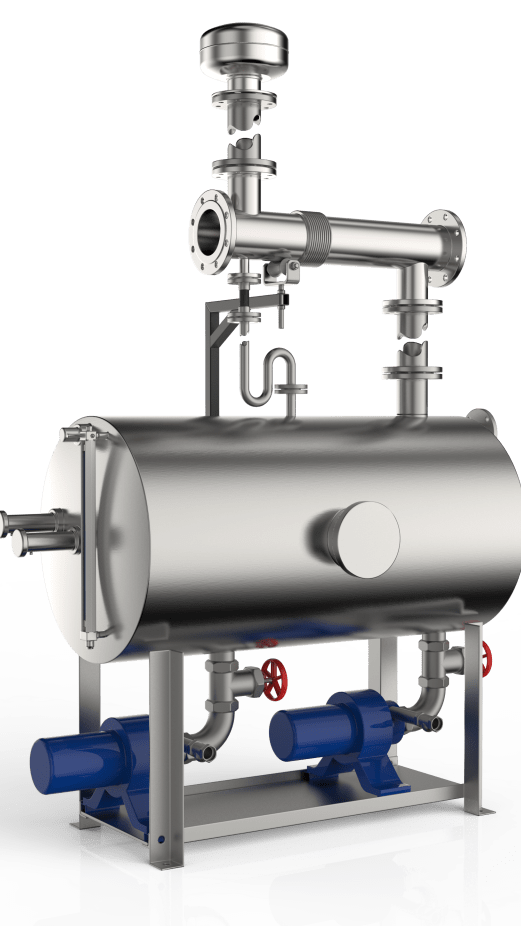

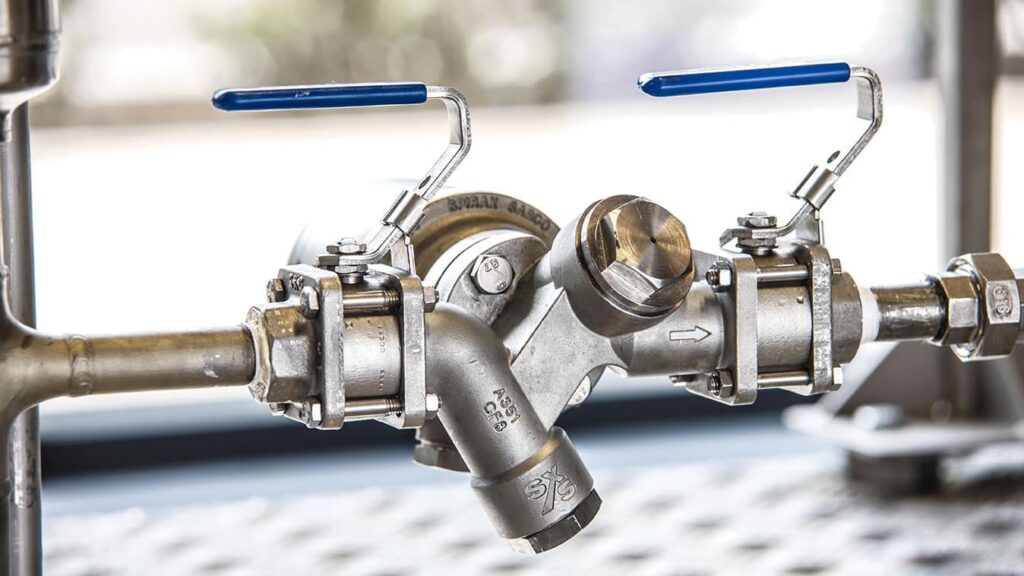

Steam can heat or sterilize almost any industrial process. That’s why Spirax Sarco products is the first often for steam solutions.

From food producing to oil refining, beer making, and drug manufacturing companies, steam is well known for delivering safe, sustainable and efficient energy.