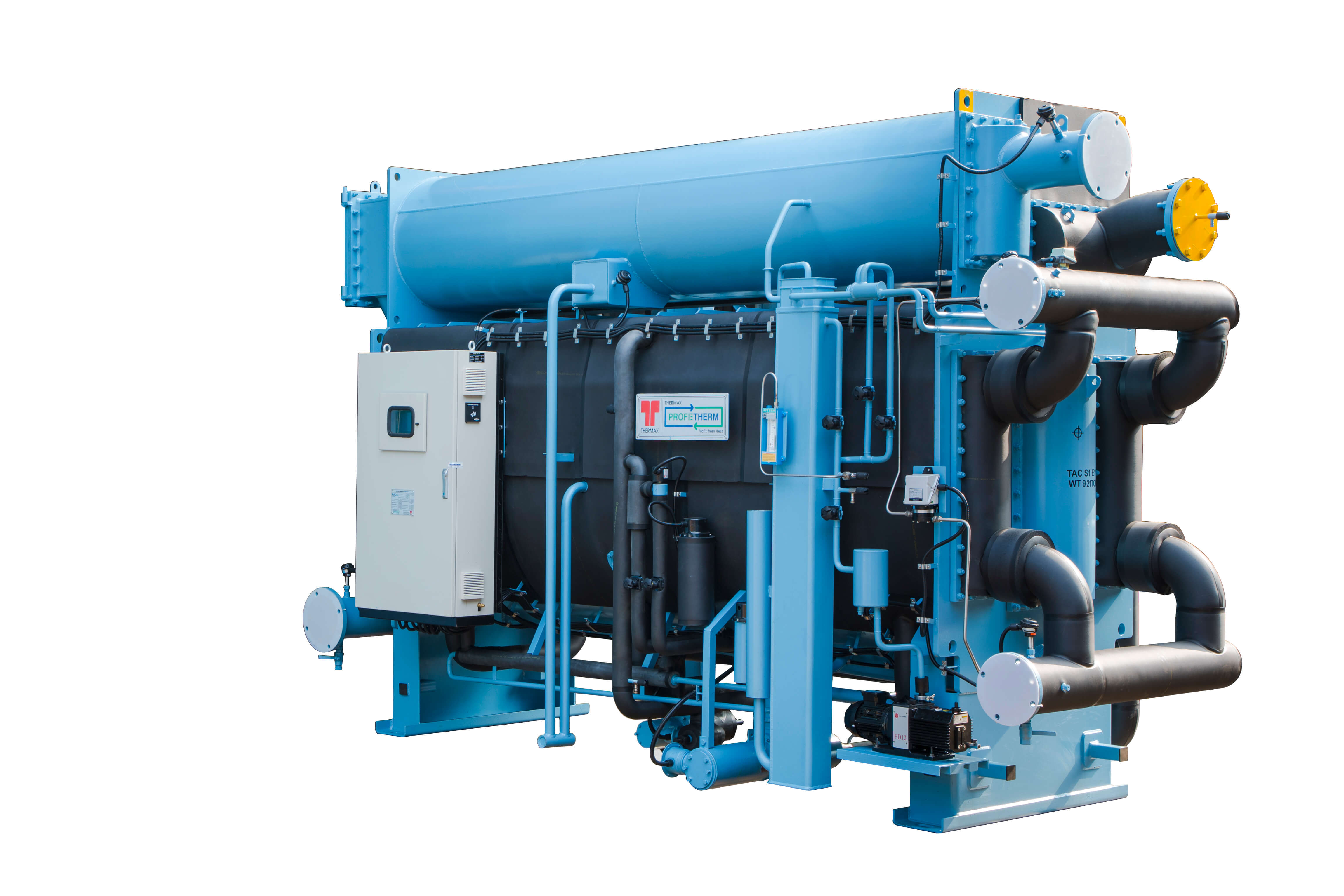

We help customers cool down the excess heat generated in their industrial processes. This ensures industrial process quality, reliability, and equipment durability. We offer turn-key industrial cooling solutions, from design to implementation and service.

-

Heat dissipation and temperature control

Many industrial processes generate heat, whether from machinery, equipment, or chemical reactions. Cooling systems help dissipate this heat, preventing overheating of machinery and ensuring optimal operating conditions.

-

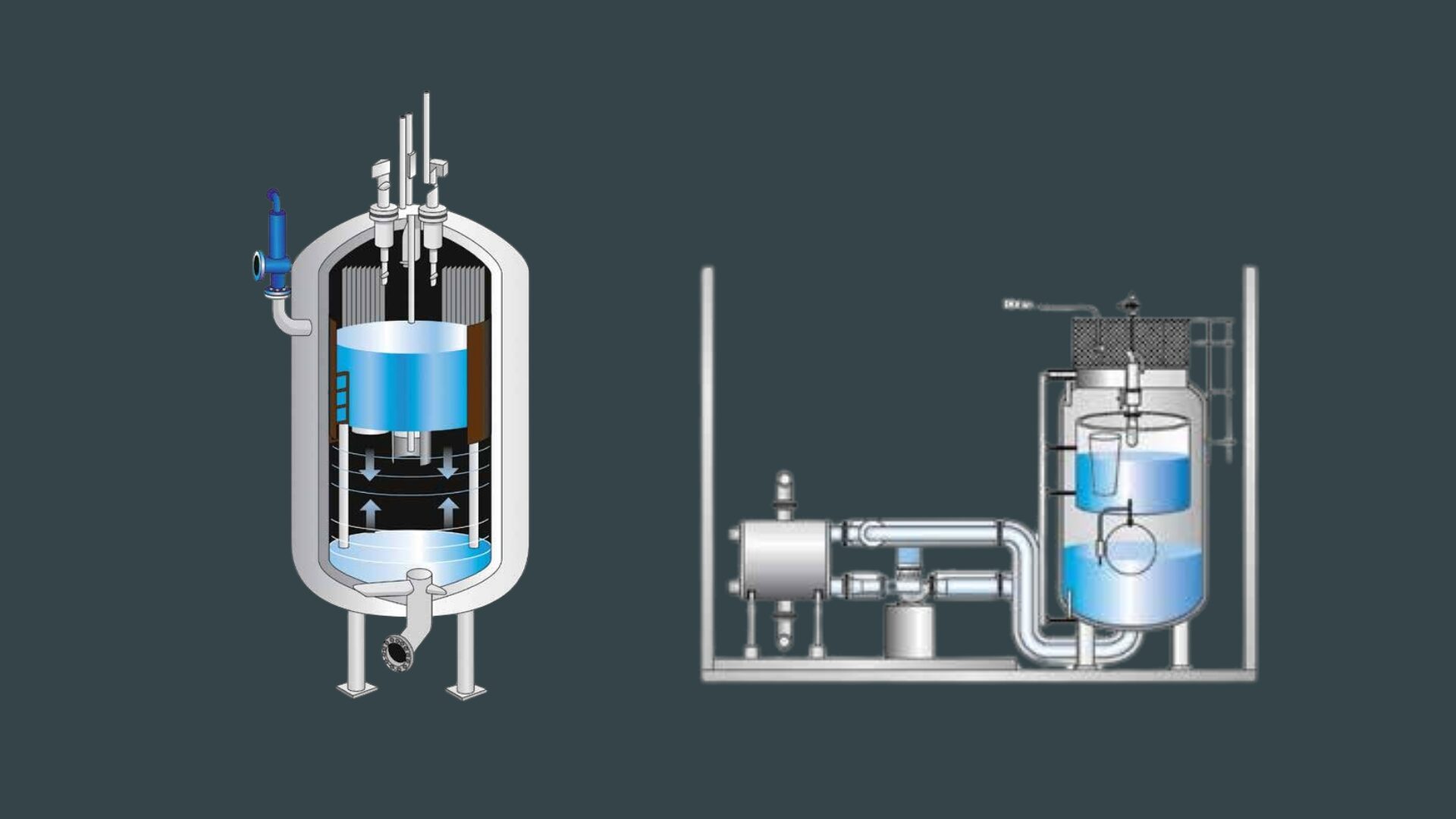

Customized solutions

Thorough analysis of the solution and its suitability to the customer's requirements.

-

Quality

Equipment that meets the highest standards of quality and performance.

-

Process efficiency

Optimized energy consumption, reduced operational costs and environmental impact. "Out-of-the-box" smart solutions where customer can avoid energy loss to the environment, instead - sending it back to the process.

-

Safety

Cooling systems contribute to a safe working environment by preventing the risk of overheating, fires, and explosions, ensuring compliance with safety regulations.