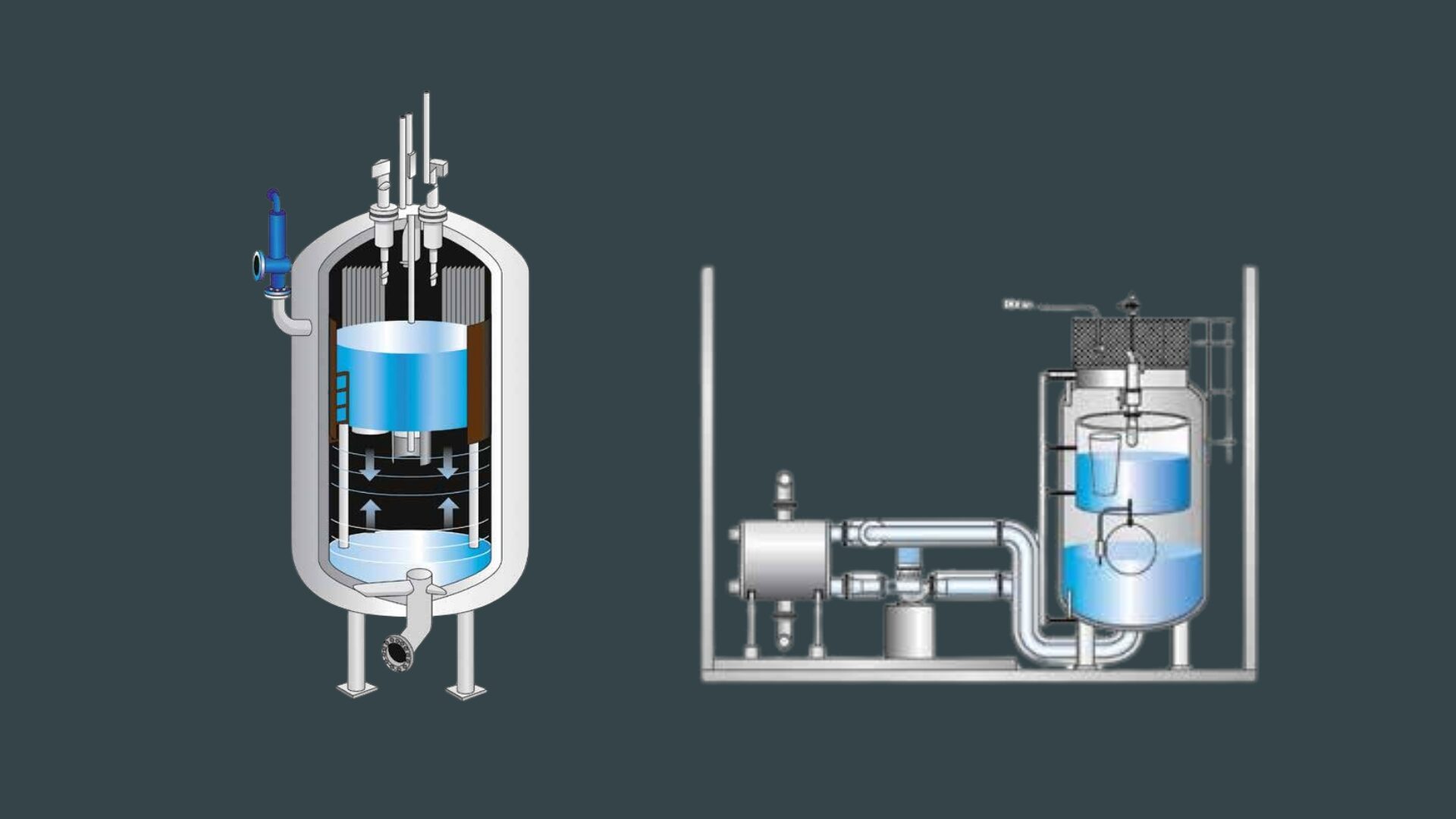

Heat pumps are one of the key technologies toward a carbon-free world. Industrial heat pump solutions provide sustainable and energy-efficient heating options for various industrial processes. These solutions harness renewable energy sources like air, water, ground or waste heat to reduce environmental impact while maintaining consistent and cost-effective heating.

-

Replacing expensive fossil fuels

-

Reducing CO2 emissions

-

Efficient waste heat recovery

-

Combining heating and cooling

-

Ensuring reliability and energy efficiency