In an era where sustainability and cost-efficiency are extremely important, industries worldwide are seeking innovative ways to optimize their energy usage. Energy efficiency is not just a buzzword but a critical component for businesses aiming to reduce operational costs, improve productivity, and meet strict environmental regulations. Let’s dive into the top three industrial energy-efficient solutions that are revolutionizing the sector.

Transitioning to greener energy solutions

In today’s industrial landscape, energy efficiency has become one of the main focuses. Companies are continuously seeking ways to reduce costs, improve operational efficiency, and minimize their environmental impact. Transitioning to greener energy solutions is no longer just a trend – it’s a necessity. Advanced technologies such as Combined Heat and Power (CHP) plants, biogas systems, and heat recovery mechanisms are leading the change. These energy-efficient solutions offer substantial benefits, from cost savings to improved sustainability.

The importance of energy efficiency in industry

Energy efficiency in industrial settings is crucial for several reasons. Firstly, the industrial sector is one of the largest consumers of energy globally, making it a significant contributor to greenhouse gas emissions. By adopting energy-efficient solutions, industries can play an important role in combating climate change. Secondly, energy costs constitute a substantial portion of operational expenses. Implementing energy-saving solutions can lead to considerable cost reductions, thereby improving the overall profitability of a business. Lastly, regulatory pressures and the growing demand for sustainable practices from consumers and stakeholders are pushing industries towards greener energy solutions. Embracing these solutions not only guarantees compliance but also improves the company’s reputation as a responsible corporate citizen.

Case studies: successful implementation of efficient energy systems

To illustrate the effectiveness of energy-efficient solutions, let’s look at some real-world case studies. These examples highlight how industries have successfully transitioned to greener energy solutions and reaped the benefits. By examining these success stories, we can gain insights into the practical applications of advanced technologies and understand the significant positive impacts on operational efficiency, cost savings, and environmental sustainability.

Learn more about energy solutions

1. CHP Plants – the future of industrial energy efficiency

Let’s begin by understanding what a CHP plant is. Combined Heat and Power (CHP) plants represent a cornerstone of modern energy-efficient solutions. These systems generate electricity and capture the heat that would otherwise be wasted, utilizing it for heating purposes. The result is a significant boost in energy efficiency and a reduction in greenhouse gas emissions. By maximizing the use of energy from a single fuel source, CHP plants achieve efficiencies of up to 80%, making them an important technology for industries aiming to improve sustainability and reduce operational costs.

The advantages of CHP plants for sustainable energy

CHP plants offer several advantages for sustainable energy production. By simultaneously generating electricity and useful heat, CHP plants can achieve efficiency levels of up to 80%, compared to the average 50% efficiency of conventional power generation. This high efficiency translates into lower fuel consumption and reduced emissions, making CHP an ideal solution for industries looking to improve their solutions for green energy and sustainability.

One of the primary benefits of CHP plant efficiency is its ability to provide decentralized energy production. This means that energy is produced close to where it is consumed, reducing transmission losses and bettering energy security. Furthermore, CHP plants can operate on various fuels, including natural gas, biogas, and biomass, providing flexibility and resilience in energy supply.

Cost and operational benefits of implementing a CHP plant

The cost of a CHP plant varies depending on its size and configuration, but the long-term savings can be substantial. Operational benefits include reduced energy costs, better energy security, and greater resilience to energy price fluctuations. Furthermore, CHP plants can provide a reliable power supply, reducing the risk of downtime in industrial operations, so the CHP plant cost is well worth it.

Industries that have implemented CHP plants have reported significant savings in their energy bills. For example, a manufacturing facility that installed a gas engine CHP plant operation experienced a 30% reduction in energy costs within the first year of operation. Additionally, the facility benefited from improved operational efficiency and a reduction in greenhouse gas emissions, demonstrating the comprehensive advantages of CHP technology.

Learn more about CPH plant solutions

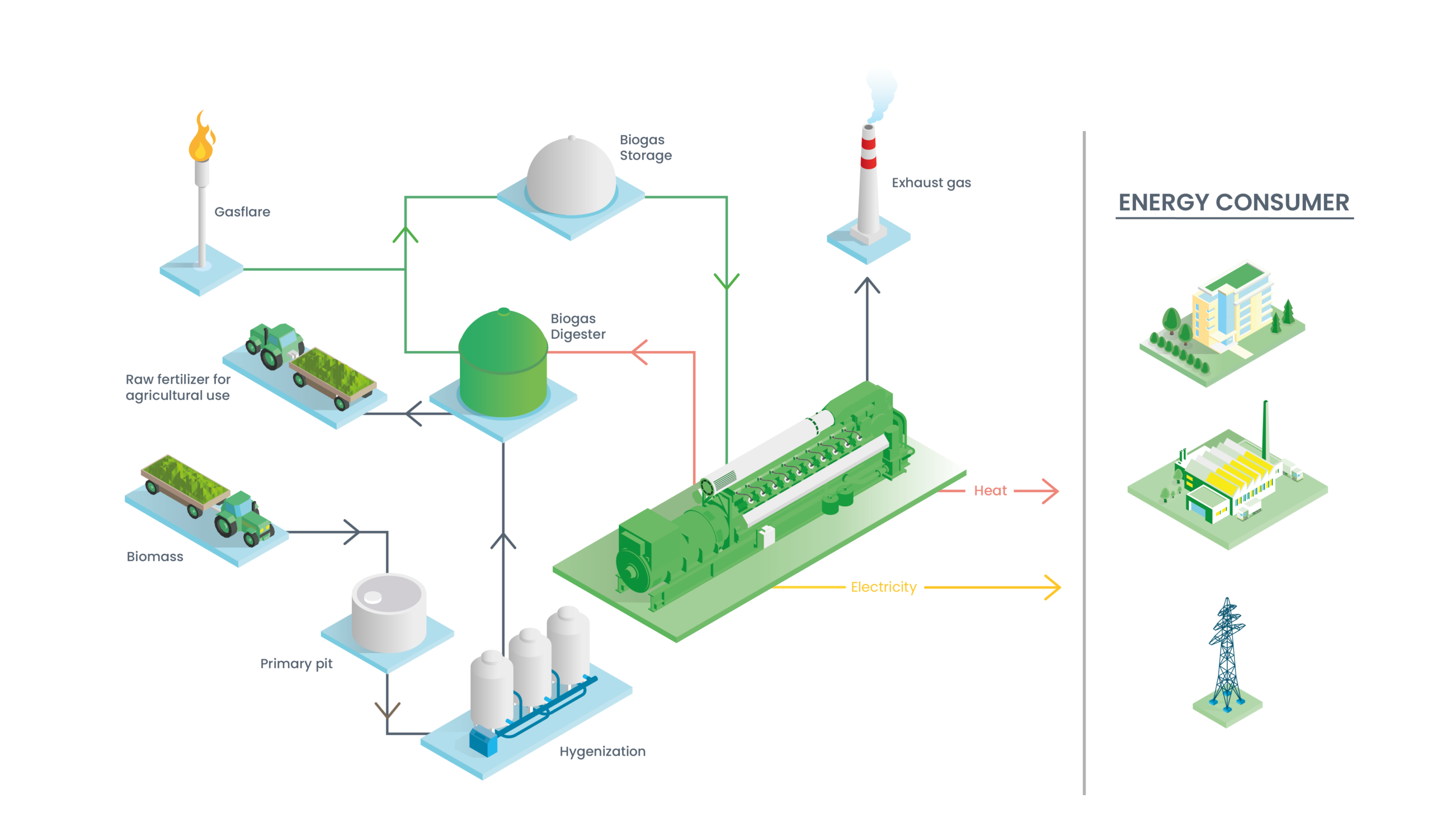

2. Biogas – renewable and sustainable power generation

Biogas is another key player in the world of renewable and sustainable power generation. Produced from organic waste materials, energy from biogas is a versatile energy source that can be used to generate electricity, heat, and even fuel for vehicles.

Generating electricity with biogas plants

Biogas power plants convert organic waste into electricity-generation from biogas through a process called anaerobic digestion. The biogas produced can then be used to generate electricity, either through biogas generators or CHP plants. This not only provides a renewable source of energy but also helps in managing waste effectively.

Anaerobic digestion involves the breakdown of organic matter by microorganisms in the absence of oxygen. The process produces biogas, which primarily consists of methane and carbon dioxide. The methane can be used as a fuel to generate electricity and heat, while the remaining digestate can be used as a nutrient-rich fertilizer, closing the loop on waste management and energy production.

Implementing biogas solutions

Implementing biogas fuel cell power plants in industrial settings involves several steps. Initially, it requires assessing the availability of organic waste materials and designing a system that can efficiently convert this waste into biogas. Companies can buy biogas electricity plants or work with providers to develop customized solutions. The benefits include reduced waste disposal costs, lower greenhouse gas emissions, and the generation of renewable energy.

For instance, a large agricultural company implemented a biogas system to process livestock manure and crop residues. The biogas electricity generator not only generated electricity to power the farm but also provided heat for various processes. This implementation led to significant cost savings, improved waste management, and a reduction in the farm’s carbon footprint.

Learn more about energy solutions

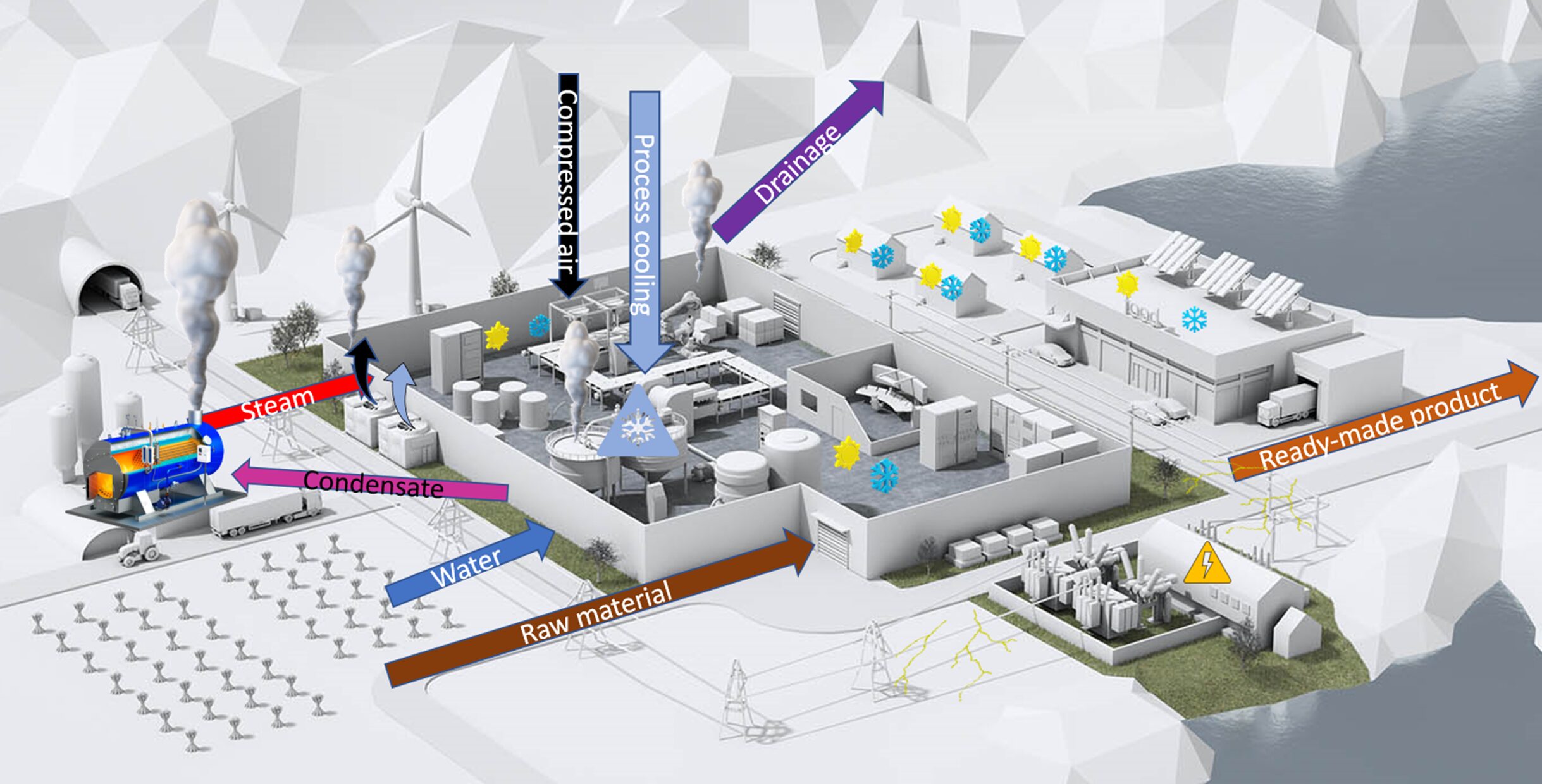

3. Heat recovery – enhanced energy efficiency

Heat recovery systems are crucial for enhancing energy efficiency in industrial processes. These systems capture and reuse waste heat that would otherwise be lost, thereby improving overall energy efficiency and reducing operational costs. By recovering this excess heat and converting it into useful energy, industries can significantly lower their energy consumption and greenhouse gas emissions. This not only helps in conserving natural resources but also contributes to a more sustainable and cost-effective operational framework.

Heat recovery steam generators: boosting plant performance

Heat recovery steam generators (HRSGs) are commonly used in power plants and industrial facilities to improve energy efficiency. These systems capture waste heat from gas turbines or industrial processes and use it to produce steam, which can then be used for power generation or heating purposes. HRSGs significantly boost plant performance and contribute to energy savings.

Heat recovery steam generators are particularly effective in combined cycle power plants, where they capture the waste heat from gas turbines to generate additional electricity. This process can increase the overall efficiency of the power plant to over 60%, compared to the 30-40% efficiency of simple cycle gas turbine plants. The increased efficiency results in lower fuel consumption and reduced greenhouse gas emissions.

Waste heat recovery: turning excess heat into value

Waste heat recovery involves capturing excess heat from industrial processes and converting it into useful energy. Techniques for waste heat recovery include using heat exchangers, flue gas economizers, steam boilers, heat pumps, and HRSGs. By recovering waste heat, industries can reduce their energy consumption, lower their carbon footprint, and improve overall efficiency.

A chemical manufacturing plant implemented a recovering waste heat system to capture heat from its exhaust gasses. The recovered heat was used to generate steam, which powered various processes within the plant. This not only reduced the plant’s energy consumption but also lowered its operating costs and greenhouse gas emissions, showcasing the significant benefits of recovery of waste heat.

Learn more about energy recovery solutions

Filter is powering sustainable energy solutions

Filter is helping industries transition to more sustainable and energy-efficient practices. Through innovative technologies and comprehensive energy solutions, Filter supports industries in achieving their smart energy consumption goals. Filter offers end-to-end solutions – from feasibility studies to design, construction, and maintenance – that guarantee optimal performance and efficiency. Their approach begins with a thorough assessment of the client’s energy needs, resulting in customized CHP solutions that deliver maximum efficiency and cost savings, backed by ongoing support and maintenance.

Filter’s expertise extends to biogas solutions, allowing industries to generate electricity from organic waste, thereby enhancing energy-saving solutions and waste management. These scalable solutions include feasibility studies, project financing, and regulatory compliance assistance, making ground for seamless integration into industrial operations. Furthermore, Filter excels in advanced heat recovery systems, helping industries recover and utilize waste heat to improve overall greener energy solutions. These solutions, such as heat recovery steam generators, heat recovery steam boilers, and heat exchangers, capture waste heat from industrial processes and convert it into usable energy, significantly reducing energy consumption, operating costs, and environmental impact. With the possibility to save energy, there is also a significant chance to save water as well as most of the industrial heat pump solutions help to transform open water circuits into closed loops (like with cooling systems) thus reducing the amount of fresh water usage as well as waste water flow rates.

Filter, with its comprehensive range of energy solutions, is well-positioned to support industrial clients in their journey towards green energy solutions and sustainability. For more information on improving industrial energy efficiency with green energy solutions, get in contact with us. Embrace the future of industrial energy efficiency with Filter and make a positive impact today!