The Liepāja Drinking Water Terminal achieved the highest national recognition in Latvia’s construction sector for 2024: the Grand Prix at the Latvian Construction Annual Award. This monumental facility – capable of storing up to 97,000 m³ of drinking water – stands as a powerful example of innovative engineering, sustainability, and international collaboration. At the heart of this project lies FILTER’s engineering and automation expertise.

A visionary infrastructure with global impact

Located near the historic Karosta swing bridge in Liepāja, the terminal is designed to collect deep well water, store it securely, and deliver it efficiently to tankers for export via sea. The 2.5 km long pipeline network and marine loading platform make this a one-of-a-kind installation globally. Designed to maintain a stable 6–8°C water temperature year-round, the terminal integrates cutting-edge technologies and environmental considerations, including a fully green roof covering the massive reinforced concrete reservoirs.

FILTER’s technological solution

FILTER was entrusted with one of the most critical components of the project: engineering and automating the water intake, storage, and export systems. FILTER’s role involved:

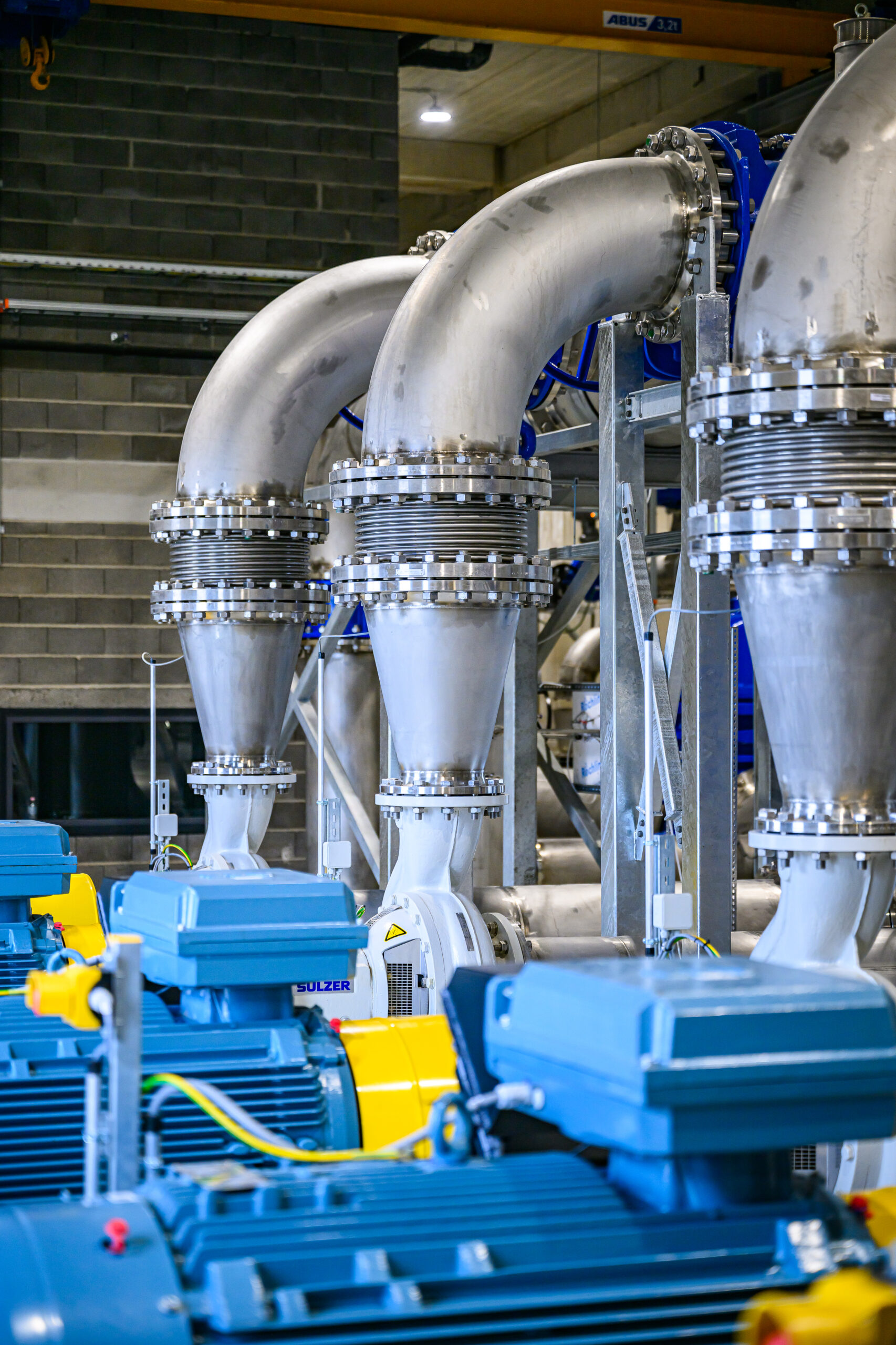

1. High-performance pumping system

FILTER developed a high-efficiency pumping solution using five 350 kW pumps, each delivering 1,000 m³/h, operating in cascade mode for a total flow of up to 4,000 m³/h. These pumps are powered by next-generation IE5 synchronous reluctance motors, ensuring maximum energy efficiency and minimal environmental impact.

All system components – including the one-meter diameter stainless steel pipes and oversized certified valves – are fully food-grade compliant, a crucial factor for safely handling potable water.

2. Advanced automation systems

Automation was central to the terminal’s success. FILTER’s automation team, led by Andris Bēniņš, implemented a redundant Siemens-based control system designed for hot-swapping. If one controller fails, another instantly takes over – ensuring continuous operation at all times.

The automation system handles:

- Secure water intake from Liepāja’s municipal network

- Real-time monitoring and visualization

- Water purity assurance

- Precise ship loading logistics, avoiding overload and ensuring synchronized flow

Custom algorithms and duplicated sensors further enhance system resilience, ensuring reliable operations even under peak loads.

Engineering with a green vision

FILTER’s involvement extended far beyond technical implementation – it was about crafting a sustainable, scalable solution for the future of water logistics. This project posed unique challenges:

- Maintaining stable water temperatures

- Balancing low intake and high output flow dynamics

- Designing for hygienic operation and minimal environmental disruption

“When we were offered to design the technology and automation for this vast project, it was clearly ambitious by Latvian standards. But with our experience, we developed a solution tailored to the unique scale and requirements. The equipment at the site exceeded our imagination – stainless steel pipes with a diameter of one meter and valves significantly larger than human size were installed. Seeing it all come together in reality was a powerful reminder of the scale and impact of this infrastructure.”

– FILTER Latvia Project Manager Dāvis Alsbergs

Why this terminal matters?

The Liepāja terminal is more than an engineering marvel – it’s a strategic step forward in securing clean drinking water for drought-stricken regions worldwide. As climate change accelerates global water scarcity, the ability to export high-quality underground water is no longer a concept, but a necessity. Latvia’s geological abundance is now supporting global needs, and FILTER is proud to contribute to this international mission.

FILTER – a trusted partner in industrial innovation

With over 30 years of experience in water treatment, energy systems, and industrial automation, FILTER continues to deliver reliable, forward-looking solutions. The Liepāja terminal joins a growing list of prestigious, high-impact projects showcasing FILTER’s dedication to quality, sustainability, and innovation.