Flue gas cleaning systems play a crucial role in reducing harmful atmospheric emissions, protecting public health, and ensuring compliance with stringent environmental regulations. These systems also contribute to technological advancements and economic benefits, fostering sustainable industrial practices and reducing the ecological footprint of industries worldwide.

Industrial emissions often contain pollutants such as sulfur dioxide (SO₂), nitrogen oxides (NOₓ), carbon monoxide (CO), and particulate matter. Without proper filtration, these substances can lead to severe air pollution, negatively impacting ecosystems and human health. Implementing flue gas cleaning technologies ensures a cleaner, safer environment while aligning businesses with global sustainability goals.

The importance of flue gas cleaning filters

1. A cleaner and sustainable living environment

A clean and sustainable environment is essential for human health and ecological balance. Flue gas cleaning filters help minimize industrial emissions, reducing air pollution and its associated risks, such as respiratory diseases and climate change. By adopting eco-friendly technologies, industries can contribute to a greener future.

2. Compliance with environmental regulations

Governments and international regulatory bodies have set strict emission standards to control air pollution. Non-compliance can lead to hefty fines, legal actions, and operational shutdowns. Flue gas cleaning filters ensure that industries meet these requirements, avoiding legal complications and reinforcing environmental responsibility.

3. Driving technological innovation

Flue gas cleaning systems push industries toward innovation by encouraging the development of cleaner, more efficient processes. This shift not only improves operational efficiency but also creates new job opportunities in environmental technology and sustainability sectors, fueling economic growth and green advancements

4. Economic benefits for industries

Investing in flue gas cleaning technologies can yield significant economic benefits. By reducing emissions, businesses can lower environmental damage costs, minimize healthcare expenses related to pollution-induced diseases, and prevent regulatory fines. Furthermore, an eco-friendly reputation enhances brand value, attracting environmentally conscious customers and investors.

Industries benefiting from flue gas cleaning systems

Energy industry – power plants and cogeneration stations that rely on fossil fuels or biomass produce substantial emissions. Advanced filtration systems play a crucial role in capturing ash, sulfur dioxide, and nitrogen oxides, helping these facilities meet environmental regulations and reduce air pollution.

Manufacturing and processing – cement plants release dust, heavy metals, and chemical byproducts, while smelting and metal processing industries emit metal particulates and toxic compounds. Flue gas cleaning systems effectively remove these pollutants, minimizing their environmental impact and improving air quality.

Woodworking industry – wood processing generates dust, resin, and other airborne contaminants that can compromise air quality and workplace safety. Specialized flue gas cleaning solutions efficiently filter out these pollutants, creating a cleaner and healthier work environment.

Biogas production – before biogas can be converted into energy, it must be purified to remove harmful impurities. Flue gas cleaning technologies optimize this process, enhancing energy efficiency while reducing environmental impact.

Advanced flue gas cleaning technologies

1. Bag filters

Bag filters provide up to 99% efficiency in capturing particulate matter, making them ideal for industries requiring fine dust removal, such as power generation and woodworking. They also offer low maintenance costs and long operational life, enhancing their cost-effectiveness

2. Electrostatic precipitators (ESP)

Electrostatic precipitators use electrical charges to capture fine particles. Their efficiency and durability make them suitable for high-temperature applications like industrial boilers and power plants. Additionally, they have low energy consumption, making them a sustainable option for long-term emission control.

3. Scrubbers

Scrubbers neutralize pollutants using water or chemical solutions. These systems are particularly effective in reducing sulfur dioxide, nitrogen oxides, and particulate emissions, benefiting industries such as chemical manufacturing and biogas production. They can also handle multiple pollutants simultaneously, increasing their versatility across various applications.

Scrubbers neutralize pollutants using water or chemical solutions. These systems are particularly effective in reducing sulfur dioxide, nitrogen oxides, and particulate emissions, benefiting industries such as chemical manufacturing and biogas production. They can also handle multiple pollutants simultaneously, increasing their versatility across various applications.

4. Cyclones and multicyclones

Using centrifugal force, these systems separate larger particles from flue gases. They are simple and economical solutions for removing coarser particles from flue gases and are often used as the first stage of purification before installing bag filters or ESPs. While effective for primary filtration, they are often supplemented with advanced filtration methods for enhanced efficiency.

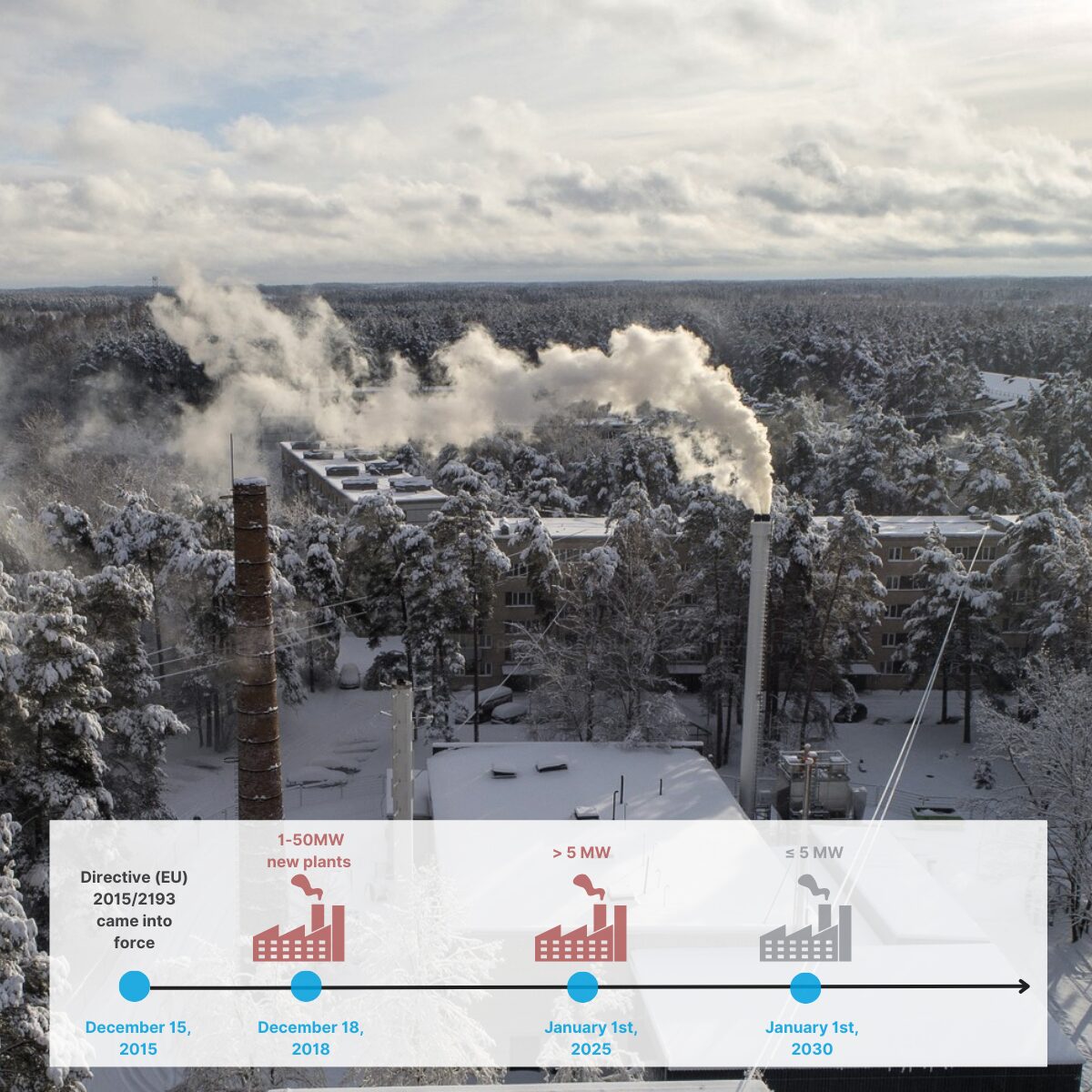

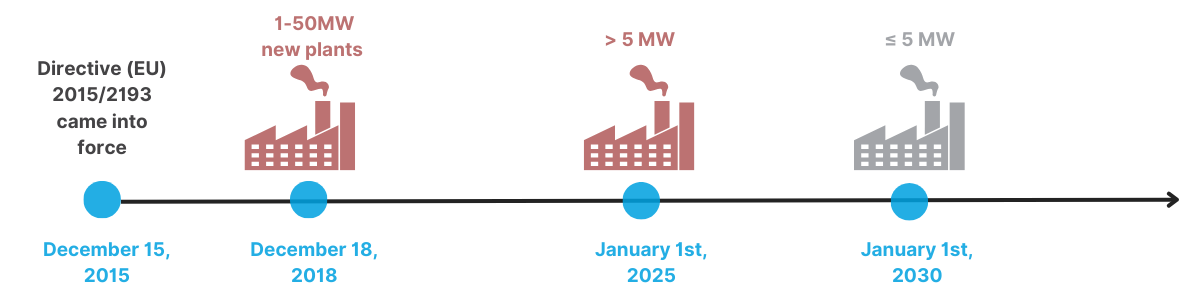

EU Emission Regulations and Compliance

From January 1, 2025, the Medium Combustion Plant Directive (MCPD) (Directive (EU) 2015/2193) mandates stricter emission limits for medium combustion plants (MCPs) with thermal input between 5 MW and 50 MW.

For new MCPs, regulations have been in effect since December 18, 2018, while existing MCPs between 5 MW and 50 MW must comply by January 1, 2025. Smaller plants between 1 MW and 5 MW face stricter limits starting January 1, 2030. Non-compliance with these regulations can result in operational restrictions, financial penalties, and reputational damage. Additionally, operators must monitor and report emissions regularly to ensure ongoing compliance. Another key requirement is the implementation of best available techniques (BAT) to further reduce environmental impact and enhance energy efficiency.

FILTER as Your trusted partner in flue gas cleaning solutions

FILTER provides smart and customized flue gas cleaning solutions to help industries achieve compliance, improve efficiency, and enhance sustainability. With extensive experience in the installation of flue gas cleaning systems within various projects, our advanced systems meet and exceed EU environmental standards, ensuring industries can reduce emissions while optimizing processes.

Through tailored designs, we help businesses improve operational efficiency and maintain long-term sustainability. As emission regulations grow stricter, investing in innovative flue gas cleaning technologies is no longer an option but a necessity. Partnering with FILTER ensures that industrial operations remain clean, efficient, and future-ready.

Contact FILTER today for tailored flue gas cleaning solutions!