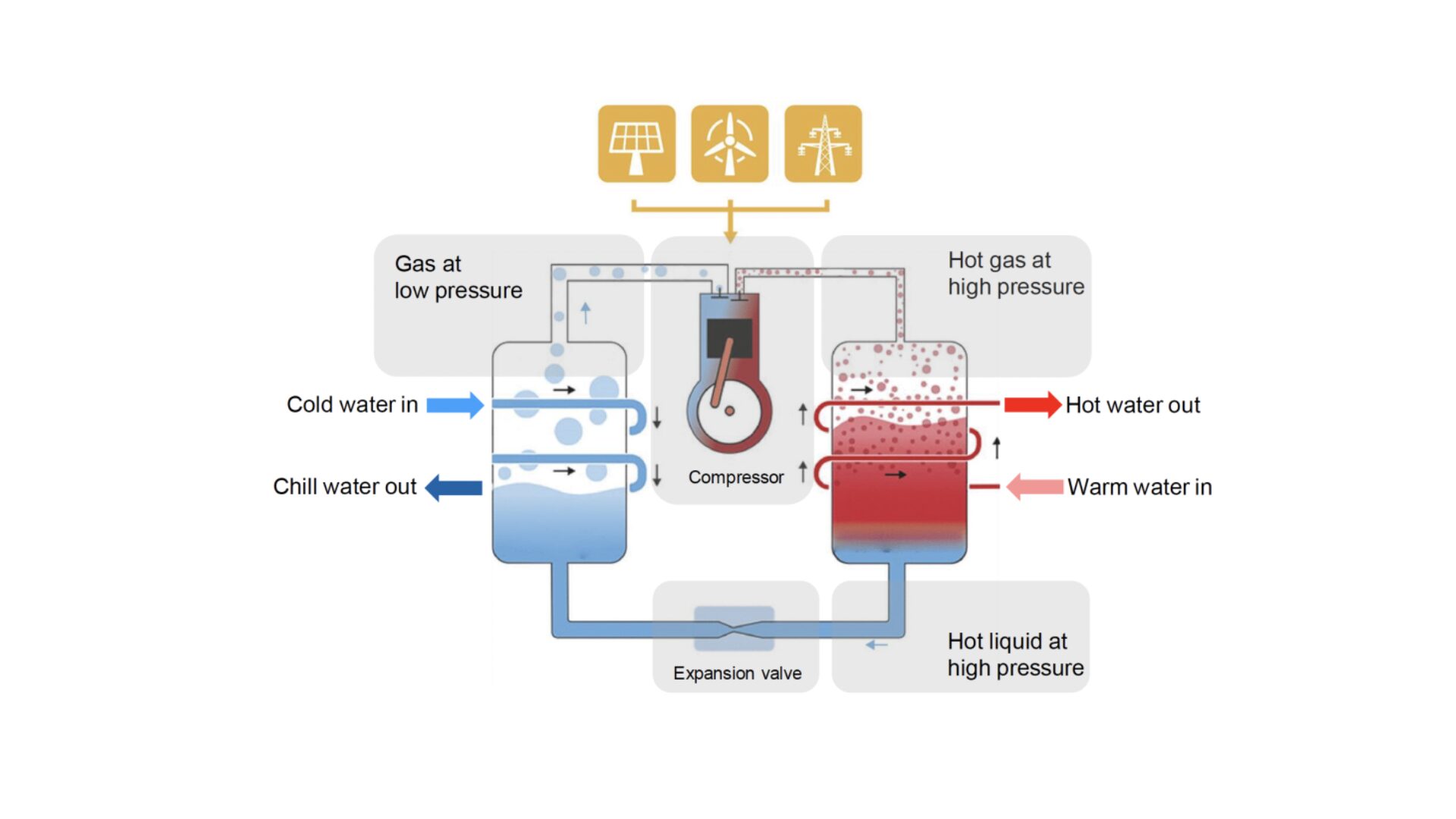

As industries across Europe transition to low-carbon operations, the electrification of heat is becoming a critical strategy. Industrial heat pumps offer a clean, efficient, and scalable solution for generating process heat and district heating. FILTER provides industry-leading heat pump systems from Oilon and Heaten, designed to meet the technical and performance demands of industrial and utility clients.

1. Industrial heat pump solutions

FILTER’s portfolio includes high-performance heat pump systems tailored for various industrial applications, from medium-temperature hot water to large-scale steam production.

1.1. Why Oilon?

Oilon ChillHeat systems offer a unique combination of efficiency, reliability, and control features, making them a preferred solution for industrial customers and district heating providers.

Key advantages:

- Market-leading efficiency (highest COP)

- Very high outlet temperatures (up to 120 °C)

- Very high temperature lift

- Wide range of refrigerants, including low-GWP options

- Excellent part-load operation (down to 20%)

- Compact footprint and integrated soundproof casing

- Low vibration and robust design

- ABB PLC-based automation with auxiliary equipment control functions

1.2. Oilon ChillHeat P-Series

The P-series is designed for mid-sized applications requiring precise control and high outlet temperatures.

Specifications:

- Capacity: 30–450 kW (EN 14511, 0/35)

- Outlet temperature: Up to 120 °C

- Piston compressor technology

- Optional VFDs on up to four compressors

- Compatible refrigerants: R134a, R450A, R513A, R515B, R1234ze, R1233zd

1.3. Oilon ChillHeat S-Series

The S-series serves large-scale heating networks and industrial processes.

Specifications:

- Capacity: 180–2000 kW (EN 14511, 0/35)

- Outlet temperature: Up to 80 °C

- Screw compressor technology

- VFDs as standard

- Broad refrigerant compatibility

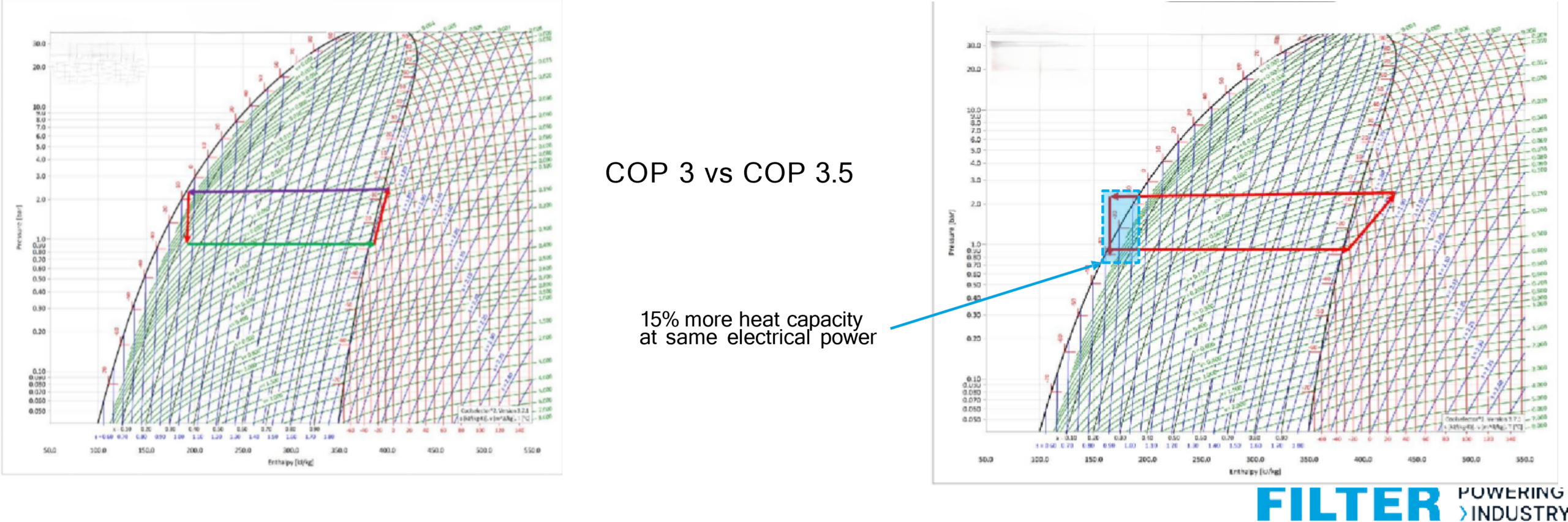

1.4. Subcooling efficiency advantage

ChillHeat systems utilize subcooling to increase heat output without added power consumption. This allows up to 15% higher capacity at the same input, significantly boosting overall COP and reducing operating costs.

1.5. Advanced automation & connectivity

Automation is delivered via ABB PLC with integrated energy metering and remote access capabilities.

Supported interfaces:

- Modbus RTU/TCP

- Profibus

- Profinet

- Bacnet

Remote connectivity is available through Tosibox, supporting remote monitoring, diagnostics, and integration with supervisory systems via OilonONE platform.

2. Steam generating heat pumps

FILTER also provides very high-temperature heat pumps capable of producing direct steam for industrial use. These systems are ideal for process industries looking to eliminate fossil-fuel boilers.

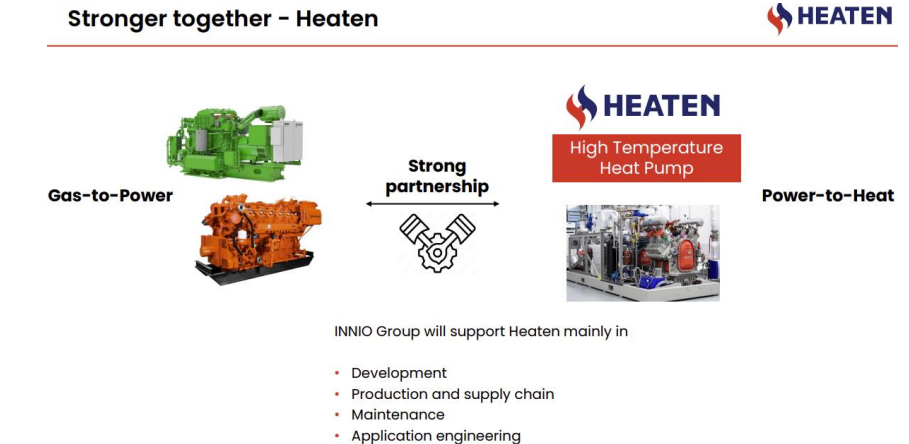

2.1. Heat pumps to decarbonize high-temperature process heat

FILTER partners with Heaten, a pioneer in high-temperature heat pump development with over 13 years of experience. Heaten’s collaboration with the INNIO Group ensures industrial-grade engineering, manufacturing, and lifecycle support.

INNIO supports Heaten with:

- Development and engineering

- Scalable manufacturing

- Global maintenance services

- Application-specific consulting

This partnership enables industrial clients to integrate Power-to-Heat technology into operations with high reliability and long-term efficiency.

2.2. The HeatBooster Technology

The HeatBooster system is a high-capacity, piston-compressor heat pump that delivers saturated steam up to 12 bar and 200 °C, ideal for industrial steam loops.

Key features:

- Robust, compact design

- Efficient part-load operation (down to 20%)

- Compatible with low-GWP refrigerants

- Stable performance in continuous operation

This system enables full electrification of steam generation without compromising process performance or reliability.

2.3. COP performance at high temperatures

COP (Coefficient of Performance) remains a critical metric for assessing heat pump efficiency. Even at high delivery temperatures (e.g., 150 °C), modern systems maintain COP values around 2.2, depending on the source temperature.

This demonstrates that electrified steam production is technically and economically viable, even in energy-intensive applications.

3. FILTER is powering industries with industrial and steam-generating heat pump solutions

FILTER’s portfolio of industrial and steam-generating heat pumps delivers the performance, flexibility, and sustainability required by modern energy systems. Whether optimizing process heat, replacing fossil fuel boilers, or enabling low-emission district heating, our solutions are built to meet the evolving needs of industrial operations and municipalities.

With advanced technologies from Oilon and Heaten, FILTER provides:

- Reliable, high-efficiency heat generation

- Electrification-ready systems with grid service compatibility

- Full support from project planning to commissioning and service delivery

- Proven references in the Baltic and Nordic markets

FILTER is committed to supporting your decarbonization and electrification journey with scalable, future-proof heating solutions. Partner with FILTER for the next generation of industrial heat.