This smart solution helped the customer save about four weeks of construction time at the site.

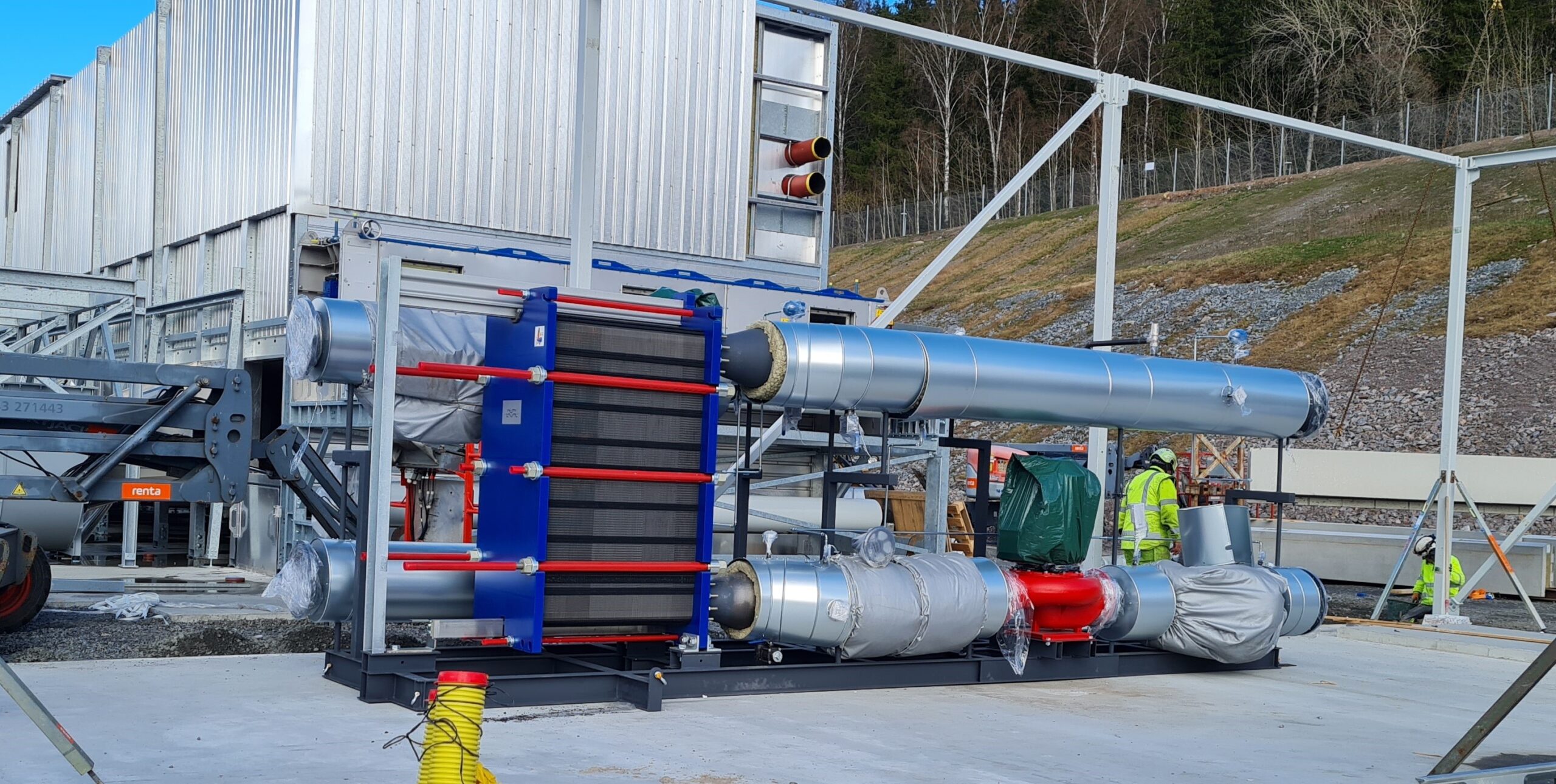

Our task was to calculate flow rates and pipe diameters, select suitable equipment, to design and build a 12 MW heat exchanger unit to supply heat energy to the wood belt dryer.

Primary side data: Water 120/92 °C.

Secondary side data: 40% ethylene glycol aqueous solution 90/110 °C.

If possible, the heat exchanger unit had to be transported by so-called normal transport, not as special transport.

During the design process, all the equipment was placed on one frame so that it could be transported in a truck covered with a waterproof cover or so-called tent. This approach allowed the client to save construction time on the site. While the customer was constructing the buildings and installing the dryer and other equipment, a heat exchanger unit was manufactured in our workshop, which was transported directly to the site and installed in the building before the roof work began and connected to the pipelines previously brought into the building.