Water is a critical resource in industrial operations, and making sure it’s high quality is highly important for maintaining efficiency and protecting equipment. As industries strive to meet regulatory standards and better their operational performance, adopting advanced water filtration solutions has become essential.

In recent years, water reuse has gained significant traction as a sustainable practice in industrial settings. By implementing effective filtration systems, plants can treat and recycle wastewater, reducing overall water consumption and minimizing environmental impact. This approach not only conserves valuable water resources but also offers potential cost savings for industries.

Mechanical filtration serves as a cornerstone in many industrial water treatment processes. This method, which involves physically removing suspended solids and particulates from water, is often the first line of defense in a comprehensive filtration system. From simple screens to advanced membrane technologies, mechanical filtration plays a crucial role in preparing water for further treatment or direct reuse.

This guide explores top industrial water filter solutions, detailing their processes and benefits. From industrial water softener and reverse osmosis plant systems to ultraviolet filtration and deionized water treatments, let’s look at valuable details in choosing the best filtration methods to meet your specific industrial needs. Let’s dive into the world of industrial water filtration and discover how these technologies can elevate your operations!

Industrial Water Filtration Guide

Guaranteeing clean and safe water in industrial applications is crucial for maintaining efficient operations and protecting equipment. Industrial water filtration solutions are designed to remove impurities and contaminants, making sure water quality meets the required standards.

These advanced systems not only improve the longevity of machinery by preventing scale buildup and corrosion but also ensure compliance with environmental regulations. By investing in top-tier water filtration technologies, industries can optimize their processes, reduce downtime, and achieve significant cost savings in the long term. Adopting these solutions is a proactive step towards sustainable and efficient industrial operations.

Industrial Water Filtration Processes in Plants

The filtration of water in industrial plants varies depending on the specific requirements and the types of contaminants present. The primary goal is to remove impurities that can affect the performance of machinery and the quality of the products. Without proper filtration, contaminants such as minerals, chemicals, and biological matter can cause severe damage to equipment, leading to frequent breakdowns and costly repairs.

Poor water quality can also compromise product integrity, resulting in subpar outputs and potential regulatory non-compliance. The lack of effective filtration can also escalate operational costs due to increased energy consumption and maintenance needs. Therefore, implementing the correct water filtration solutions is essential to avoid these negative outcomes and guarantee smooth, efficient, and compliant industrial operations. Below are the top five industrial water filtration solutions used in plants:

1. Industrial Water Softener Systems

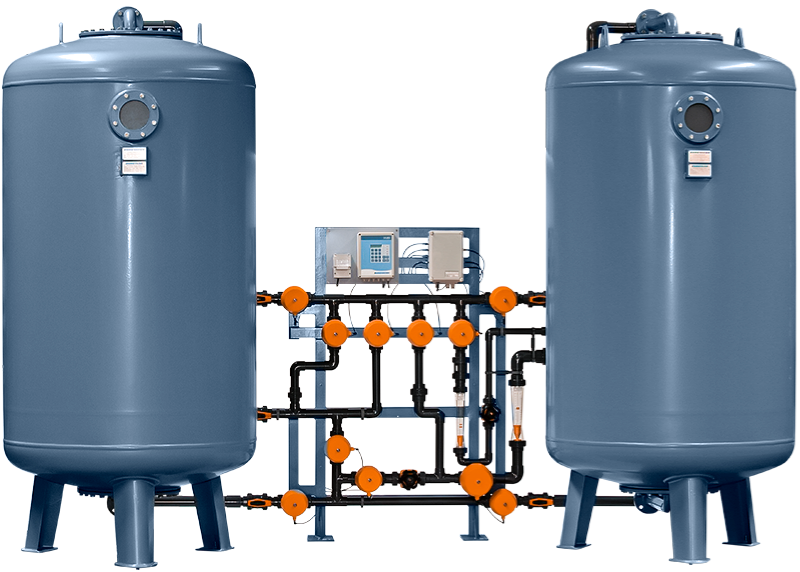

Industrial water softener systems are designed to remove minerals like calcium and magnesium from water, which cause hardness. Hard water can lead to scale buildup in pipes and machinery, reducing efficiency and increasing maintenance costs. By using ion exchange resins, industrial water softeners replace hardness ions with sodium or potassium ions, resulting in softened water that is less likely to form scale.

Industrial water softener plant systems are essential for industries where water hardness can significantly impact operations, such as boilers, cooling towers, and other equipment that involves heating processes. If you install industrial water softeners, it can prolong the lifespan of equipment and improve overall efficiency. Something to also keep in mind – softened water improves the performance of detergents and cleaning agents, leading to improved sanitation in facilities.

2. Reverse Osmosis (RO) in Plants

Reverse osmosis in plants is a highly effective filtration process of water that removes dissolved solids, contaminants, and impurities from water by forcing them through a semi-permeable membrane. RO systems are widely used in industries to produce high-purity water for various applications, including manufacturing, power generation, and food and beverage processing.

RO systems can remove up to 99% of dissolved salts and impurities, making them ideal for applications where water quality is critical. The efficiency of RO systems depends on factors like water pressure, temperature, and the quality of the feed water. Regular maintenance and monitoring are essential to maintain optimal performance. Furthermore, advancements in RO technology have led to more energy-efficient systems, reducing operational costs.

Read more about flue gas cleaning systems

3. Distilled Water Plants

Distillation is a process that involves heating water to create steam, which is then condensed back into liquid form, leaving impurities behind. Distilled water plants are used in industries that require extremely pure water, such as pharmaceuticals, laboratories, and electronics manufacturing.

The distillation process effectively removes contaminants, including salts, heavy metals, and organic compounds, making it one of the most reliable methods for producing high-purity water. However, it is an energy-intensive process, and the operational costs can be higher compared to other filtration methods. Despite the costs, distilled water guarantees the highest level of purity, which is crucial for sensitive industrial processes.

4. Ultraviolet (UV) Filtration Systems

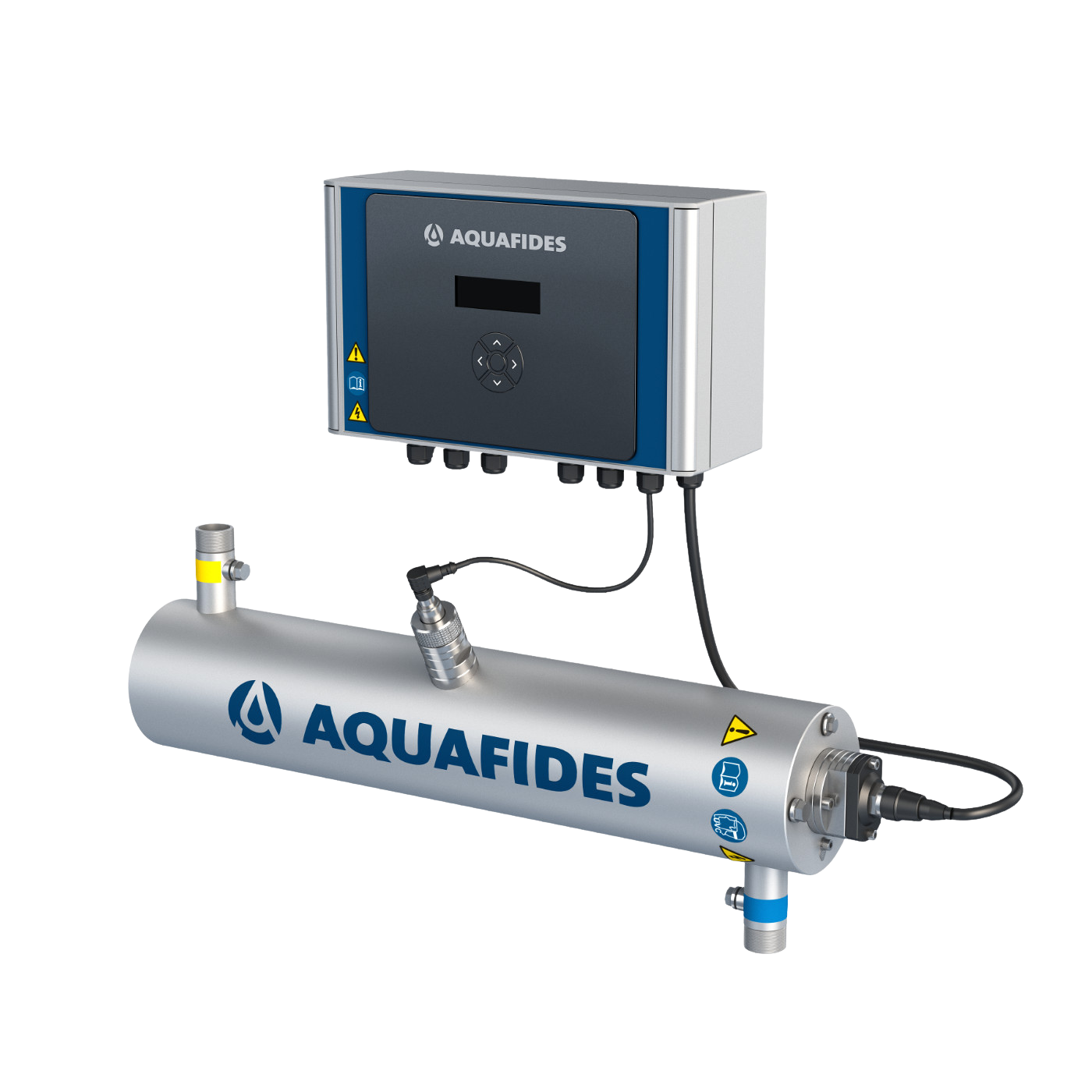

Ultraviolet (UV) filtration systems use UV light to disinfect water by deactivating microorganisms such as bacteria, viruses, and protozoa. The UV treated water method does not involve adding chemicals to the water, making it an environmentally friendly option for water treatment.

UV filtration systems are commonly used in industries where microbial contamination is a concern, such as in food and beverage processing, pharmaceuticals, and aquaculture. These systems are easy to install and maintain, and they provide a high level of disinfection without altering the taste or chemical composition of the water. Additionally, UV systems can be integrated with other filtration methods to improve overall water quality.

5. Deionized Water Treatment

Deionized water treatment involves removing ions from water through ion exchange, resulting in highly pure water free from dissolved minerals. Deionized water is used in applications that require high-purity water, such as in laboratories, pharmaceuticals, and electronics manufacturing.

Deionization is effective in removing both cations (positively charged ions) and anions (negatively charged ions) from water, making it one of the most comprehensive water purification methods. The process typically involves passing water through ion exchange resins that attract and bind the ions, effectively purifying the water. Industries using deionized water benefit from reduced scaling and corrosion in their equipment.

Other Methods – Iron, Nanofiltration, Carbon Filters

In addition to the primary filtration methods mentioned above, other techniques like iron filtration, nanofiltration, and carbon filters are also used in industrial applications. Iron filters remove iron and manganese from water, preventing staining and protecting equipment. Nanofiltration membranes are used to remove larger molecules and multivalent ions, providing a middle ground between RO and conventional filtration. Activated carbon filters are effective in removing organic contaminants, chlorine, and other chemicals, improving the taste and odor of water. These supplementary methods improve the overall efficiency and effectiveness of industrial water filtration systems.

Best Water for Plants: Filtered vs. Distilled vs. RO

Choosing the best water for industrial plants depends on the specific requirements and the contaminants present in the water supply. Filtered water is suitable for general applications, providing adequate purification for most industrial processes. The distilled water plant offers the highest level of purity, ideal for applications that require contaminant-free water. RO plants strike water a balance between purity and cost-efficiency, making it a versatile option for various industrial uses. Understanding the specific needs of the application helps in selecting the most appropriate water treatment method.

It is crucial to choose wisely and seek expert guidance when selecting a water treatment solution. Each industrial application has unique requirements, and the wrong choice can lead to inefficiencies, increased costs, and potential damage to equipment. Consulting with water treatment professionals makes sure that the chosen method aligns with the specific needs of your operation, providing optimal results. Expert guidance can help you navigate the complexities of water treatment technologies, assess the quality of your water supply, and implement a system that maximizes efficiency and reliability. This informed approach not only safeguards your investment but also improves the overall sustainability and performance of your industrial processes.

Filter and Softener Installation Costs

The cost of installing water filters and water softeners varies depending on the system size, complexity, and specific requirements of the industrial application. Factors like the quality of feed water, desired water quality, and system capacity all influence the filters and water softener installation costs. It is essential to conduct a thorough assessment and obtain quotes from reputable providers to determine the most cost-effective solution for your needs. Investing in high-quality filtration systems can result in long-term savings through improved efficiency and reduced maintenance costs.

Keep in mind that partnering with experienced professionals for installation guarantees that the system is set up correctly and operates at peak efficiency from day one. Proper water softener installation can also minimize downtime and avoid costly operational disruptions, allowing your facility to maintain consistent production schedules. By considering the total lifecycle costs and benefits, industries can make informed decisions that balance upfront expenses with long-term gains in performance and reliability.

Upgrade Your Water Treatment Plant

Upgrading your water treatment plant with advanced filtration systems can lead to significant improvements in water quality, operational efficiency, and cost savings. Modern filtration technologies offer improved performance, reliability, and ease of maintenance, making them a worthwhile investment for any industrial facility. Upgrades can also align with compliance with regulatory standards, protecting your operations from potential legal issues.

Filter is Powering the Filtration Industry

Filter is your go-to provider for innovative water treatment solutions, offering a comprehensive range of filtration systems tailored to the diverse needs of industrial clients. Our expertise in designing, implementing, and maintaining water treatment systems guarantees that you achieve optimal water quality and operational efficiency. Committed to sustainability and innovation, Filter delivers the best solutions for your water treatment needs.

Improve your industrial water treatment processes by partnering with Filter. Our innovative technologies can elevate your operations, giving you superior water quality and exceptional performance. Choose Filter to leverage the best solutions in the industry for optimal efficiency and sustainability. Let us help you achieve your water treatment goals with our innovative and reliable systems.