For short-term or one-time measurements, there is no need to buy a permanent flow meter. By renting flow meters, you save on costs, and their reuse is easy.

To install a flow meter that utilizes the ultrasonic measurement principle, commonly employed for liquid flow measurement, it is not necessary to make cuts in the pipe. Instead, the measurement is performed directly through the wall of the pipeline, with the measuring devices installed on the surface of the pipes.

The portable and pipe-recessed meter for measuring gases and liquids requires minimal plumbing for installation. Once you have installed a portable steam flow meter and completed the necessary pipe work, you can use it again in the same location without the need to stop the process for installation or removal.

- Measuring the consumption of flowing liquid or gas with rented meters allows you to assess the efficiency of the infrastructure and its alignment with reality. For example, it helps determine if flow rates are sufficient and how effective energy transfer is at different consumer points.

- The flow meter helps evaluate the efficiency of pumps, the suitability of pipes for a given flow rate and/or the transfer of heat (or cold) energy, and their suitability for specific conditions.

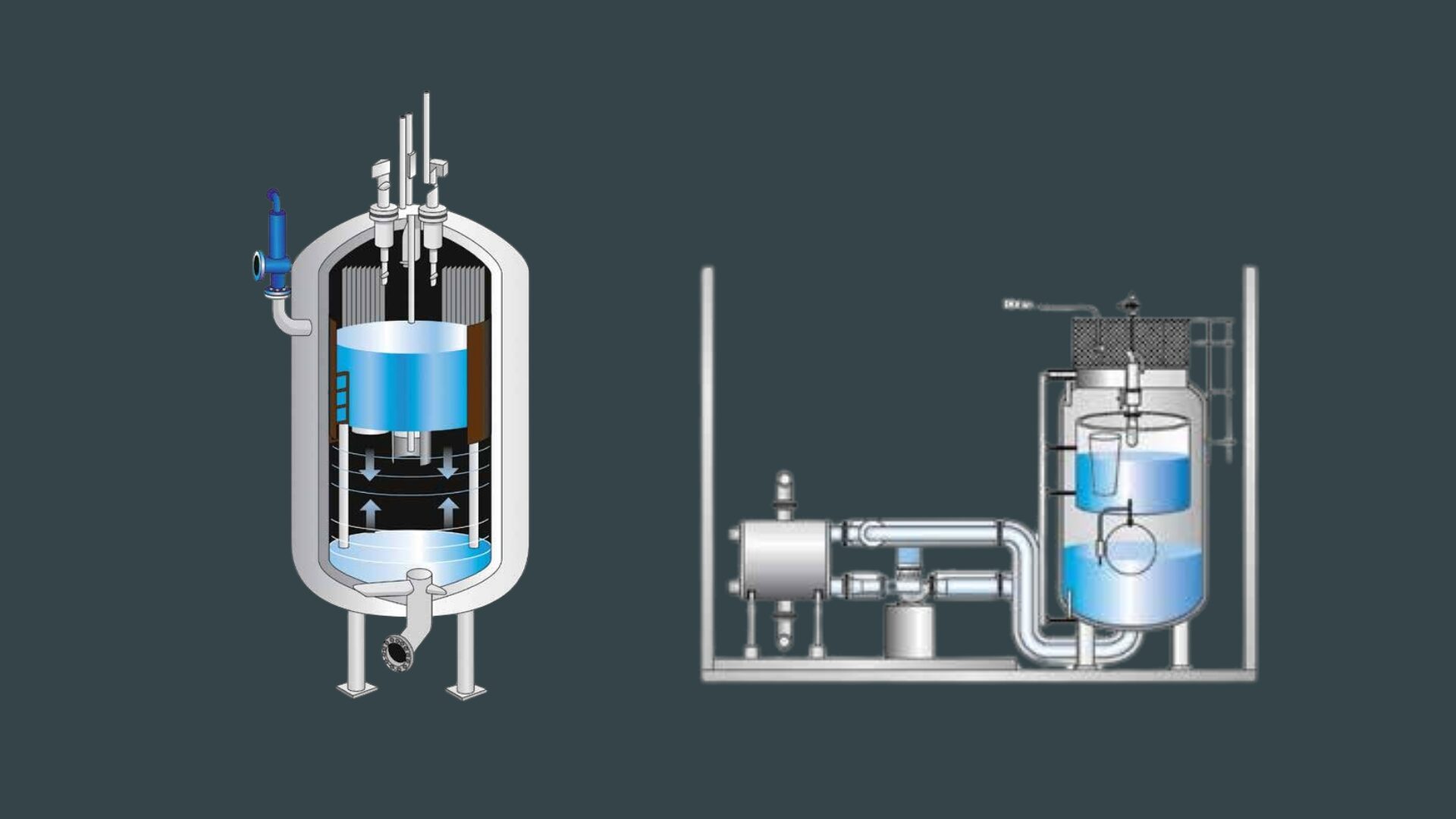

The product images are for illustrative purposes, and the actual product may appear different from the one shown in the pictures.